Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

I had to laugh when you spoke of what occurred on FB! FB and YouTube are two of my biggest nemesis from a teaching standpoint, you rarely get "good" information from either, and I cannot count the number of hours that I have spent "unlearning" students who have spent their time on either, versus actually forging. OK...enough of that.

First point, "loss" of material is a simple fact of what we do as it applies to creating Damascus, layered steel, laminate, or whatever label someone applies.

How much "loss" can depend on a great many factors, which is why there isn't a single, simple answer. That being said, and speaking only for myself, the loss I see in materials has always been due to two things.... how many times the steel goes in/out of the forge (loss from scale), and how cautious I am when it comes to "trimming" any areas that might have some MIG material left from the initial stacking, and/or how much I must grind off when re-stacking, rough grinding, or any other action that removes/takes away material. Those can also be moving targets, changing with each billet I make, and the desired outcome.

How do I overcome these issues/the loss of material? 2 things..... First, over time I have changed my shop and the tools to get layer counts up with as few heats as possible. (I run a 110lb Say-Mak air hammer, and a large 80 ton press named "Orange Crush") 😎 Large tools that allow me to work large billets, in as few heats as possible, and learning from experience, how to more closely forge to my desired level of complete, which means I have to grind away less to get to a finished item. Even with that, it's not unusual for me to see 30-50% reduction by weight for "simple" patterns, and 50-80%+ loss when it comes to Mosaics. It's just "the nature of the beast" that comes with what we do.

Of course the elephant in the room is knowing what YOUR market will bear in terms of pricing. Along with time and experience, comes building your reputation, which often has a profound impact on each Bladesmith's pricing structure. 😉

In today's world, with steel prices being so insane, I think it's prudent to calculate prices based on REPLACEMENT cost of materials rather then trying to calculate individual items. I recently purchased 1080 for Damascus. I purchased "$1,000 worth" of 6"long X 1 1/2" wide X 1/8" thick... and it ALL fit into a 5 gallon bucket!! The last time I purchased 1080 in that format, I order $750 worth, and got 5 buckets of steel 😳

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

Let’s take it from a logical deductive approach. There are only two ways to lose material in this process, the maker physically removing it via grinding, machining or cutting, and oxidation. We should be in control of, and well aware of the extent of, the first. The second is the wild card.

I recently began reviewing results in a class I teach that astounded me in material loss. I teach an advanced dagger class at various schools around the country and since its inception almost 15 years ago, I have struggled with blade thickness in the students finished blades.

At the start, not realizing the challenge the dagger blade would pose to those new to it, I assumed the thin daggers were the result of over-forging or over-grinding. I approached the issue by having them start with 3/8” thick stock in hopes that the finished dagger would not go below ¼”. But, alas, I had to eventually go to ¾” stock, in rounds or squares, to get a majority of daggers that where not too thinned out. Once again, I assumed this was due to over-hammering or over-grinding, as that is the very common case in the “Intro to Bladesmithing” classes where lack of hammer control has students over hammering the spine when forging edge bevels.

But as I observed parts of the student’s dagger blade go from 5/16” to less than 1/4, with no hammering at all, I realized that it had much less to do with the amount of hammer blows and more to do with the amount of time spent forging that challenging blade. What cemented my suspicions was when I noticed that students working in a coal forge had a better chance of producing a dagger with a 5/16 inch ricasso than those in a gas forge. It was obvious, the main culprit here was oxidation. Most of those student’s blades were on the floor around the anvil.

Gas forges are metal eaters. Having to heat an entire blade just to forge a 1” area of it moves more metal into scale than into the desired shape. And you would be surprised at how much metal you can lose to scale if it is not controlled. I have seen newer makers lose as high as 50% due to atmosphere and forging time.

What to do?

1. Use a reducing atmosphere in the forge, as most of us do, but then you get into decarb issues which is an entirely other topic.

2. Get your hot operations done with the least amount of heatS as possible, so your shaping methods have to become as efficient as possible.

3. Get your hot operations done with the least amount of heat as possible, weld at welding heat, but then draw out, or forge, at temperatures that will not help the oxygen steel your iron faster than it needs to.

4. Forge cleanly- before going to a grinder for clean-up, take your time at lower temperatures to “hammer polish” the steel, getting the surface as smooth and pit free as possible. Don’t get me wrong I love presses for welding, but here is where they fall short of a hammer, they tend to press the scale into the work instead of knocking it off like hammering does. Try this with any forging- at the end drop your temperatures to red and do a lot of rapid and, very accurate, hammer blows so that you are creating that small powdery type scale in the anvil instead of large flakes. You will notice that this forging will require very little grinding to clean up, and thus much less material loss in just getting it clean.

Thanks guys, I tried to like your posts, but for some reason, it wasnt taking.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

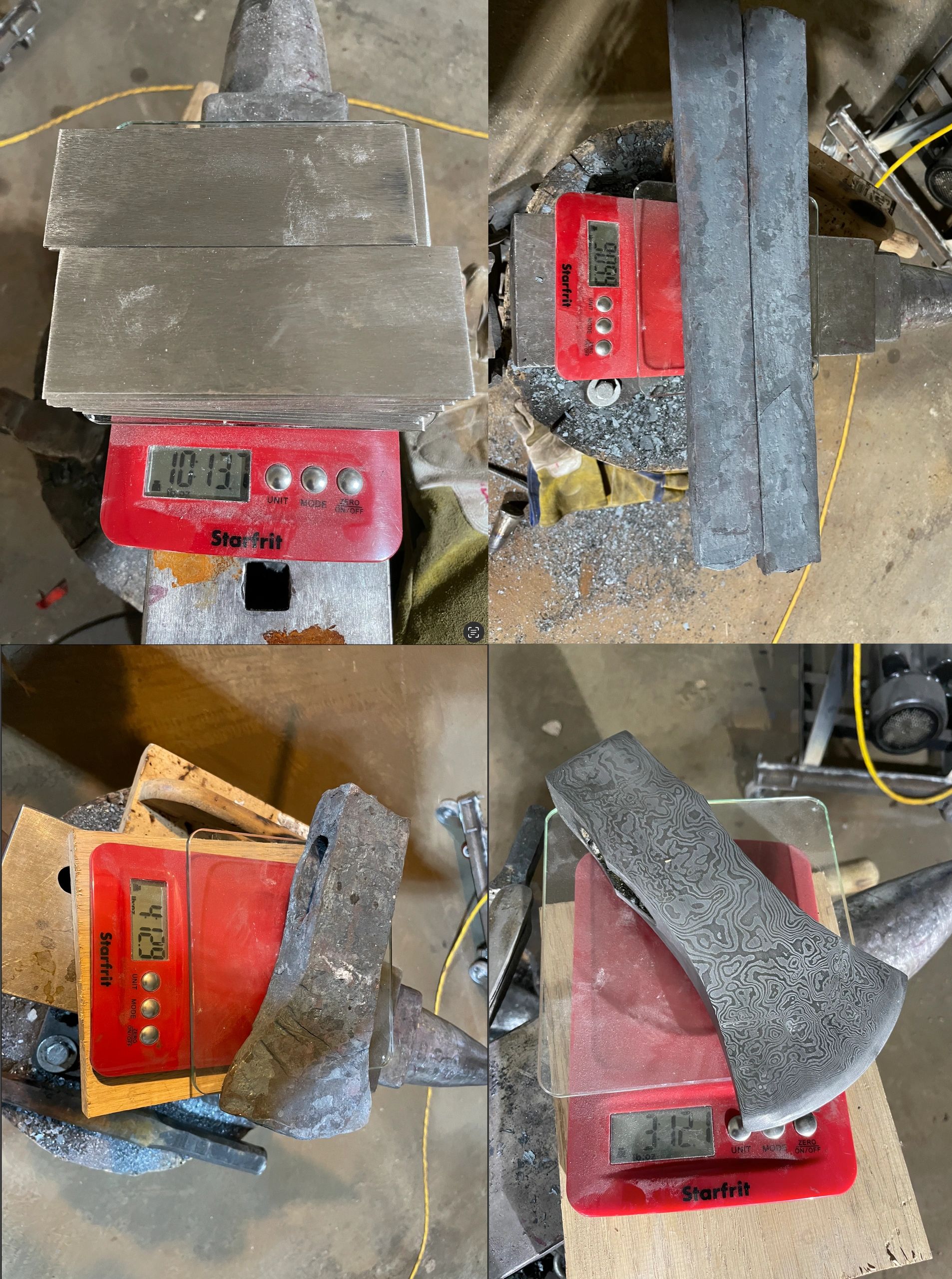

Here is the finished Axe. 300 layers. Final weight 3lbs 10 oz on a hand crafted hickory handle. I should have introduced some sort of a rainbow or ladder to really make the pattern pop more.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

The photos are first posted on my website, I usually resize them so that they have a maximum size they are a max of 1024 on the largest edge.

Then I right click on the image on the my website to copy the URL. Then paste the url in the post

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

Thats all I am doing, pasting the URL, you can also test it by previewing your post.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke