I just picked up a 25 lb Little Giant and I will likely be getting some new dies and was wondering: What dies are you guys using in your power hammers?

Here are two that I have seen for blademaking that I am thinking about so far:

The first has a flat in the middle third then a slight radius on both sides. The second has a flat on one side and a slight radius on the other.

Being that my hammer is a 25 lb Little Giant my die size would be 2'' x 3'' onless I went combo dies which are 2'' x 4''

Any thoughts?

Allen,

congrats on the new gear!

I have only ever--ever--used 2x4 combo dies. They are extremely versatile, and I hardly ever work stock wider than 2"--but even when I do I've been able to make it happen on the combo dies. I have occasionally wished for double crowned dies (top left or your image), for those few times when I want to "splay" out my material, to make a blade wider from spine to edge.

That being said, when I get my new trip hammer in a couple months, I'll be getting every type of die available, except for the extreme-radius crowning dies; I figure there will come a time when I'll need that one type for something specific, and then I'll have it on hand. Maybe foolish, maybe not. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Zack

Zack Jonas

Journeyman Smith

I use the dies like you have listed first - flat in the middle and each side with a slight radius.

Karl B. Andersen

Journeyman Smith

Zach, what kind of trip hammer are you getting?

Karl, I was just watching some of your videos last night squinting and trying to see what dies you use.

I will most likely get an Anyang. It's a self contained air hammer (no additional compressor required), and so far the one and only downside I've heard of on them is that they use lots of oil. Boo hoo. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

I've spoken extensively with the US reps for both Anyang and Say Mak, and I came to the conclusion that Anyang is a significantly better value, requiring no sacrifice of quality or versatility.

Zack

Zack Jonas

Journeyman Smith

I use the first (upper left) profile in your illustration. I have the combination dies but I dont care for them.

Anyone use the little giant die system where the dies are bolted into a dovetail for quick die swapping?

Allen,

I bought Sid's interchangeable die system for my hammer. I really like them. With the interchangeable dies, you don't have to remove the die wedge to change dies. The dies bolt into place on bases that stay in the hammer.

Sid has several types of dies available to bolt onto the bases. I bought the flat, drawing and combination dies. It only takes a few minutes to change dies.

Flat dies are nice to have, but since I have a press with flat dies, I really don't need them for my hammer. So, I took the flat hammer dies and ground them to a gentle radius. Like the upper left image that you posted. They are now perfect for forging blades. And, they are still flat enough to decently smooth out a billet of damascus.

The drawing dies that I got from Sid were flat across the top, with angled sides; like the lower left image in your post. I didn't care for the transition between the sides and the top, so I ground them to a radius. These dies are now a great set of strong drawing dies. They'll pull out a billet of damascus quickly. I use the hammer with these drawing dies to weld and draw out my damascus billets. Then, I go to the hydraulic press with flat dies to flatten the billet.

I have never used the combination dies. The two surfaces are rather small and that limits the size of material that you could work in them. They would be good for drawing out a billet of damascus on the fuller side and then flattening the billet on the flat side of the dies.

I'll try to get a photo of my dies and post them to this thread.

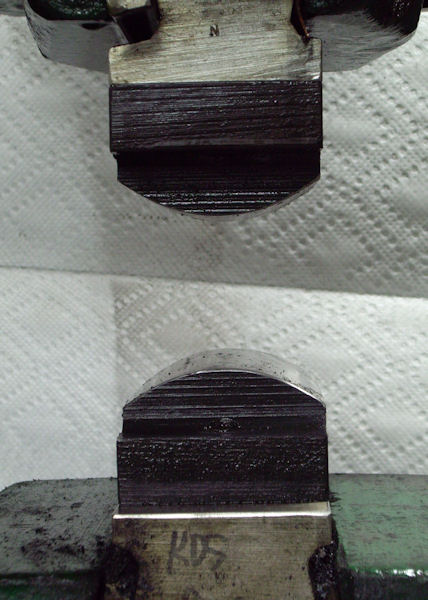

Here are photos of the dies that I use in my #50 Little giant.

These are my drawing dies. They are Sid's drawing dies that I have ground to a smooth radius, removing the transition between the sides and the flat top.

These are my blade forging dies. They were originally flat dies, purchased from Sid.

Thanks for taking the time to photograph and post your dies! I am sure that I will not be the only one to find it helpful.

I use both slightly crowned dies and flat dies when forging blades when forging billets I use a drawing dies like Culvers and extremly flat dies to stay as square as possible, I also like my dies to be as closely matched as possile so it is possible to work from all angles of the hammer, never have cared for combo dies myself, I make alot of forged one piece spurs also and need the big work faces of the flat dies I use in my Beaudrys, they are also very handy for straiting up billets if you don't have a press. If you were only making billets and could only have one hammer and one set of dies combo dies would do the trick, but if you are going to forge alot of blades with your hammer I would have some crowned dies and flat dies, YOU will be albe to tell what YOU need after foring with your hammer awhile and figue out the exact type of work you do. these are just some things I've run into over the years, hope it helps you alittle.

Willey