I thought I would share some of the tools I've made in my shop.

My brother salvaged a beat up drill press from the dump for $0.10/lb steel price. I used it for a couple years drilling pipe, square tubing, and whatnot for my local gun club. But it was missing the table, the chuck wobbled and the pulleys were slipping on their shafts. So after I replaced it I started re-purposing it for anything I could.

This is the disc grinder I built with the motor and the mounting bracket from the drill press. It pivots 90° and has an adjustable stop bolt, as I plan to someday build a horizontal tool rest for it. I do wish the motor was reversible, but I'm pretty use to working with it in just one direction.

The wood fence over the top can be placed on blocks when it's needed and has a 7° angle for setting the angle on liner locker locks...

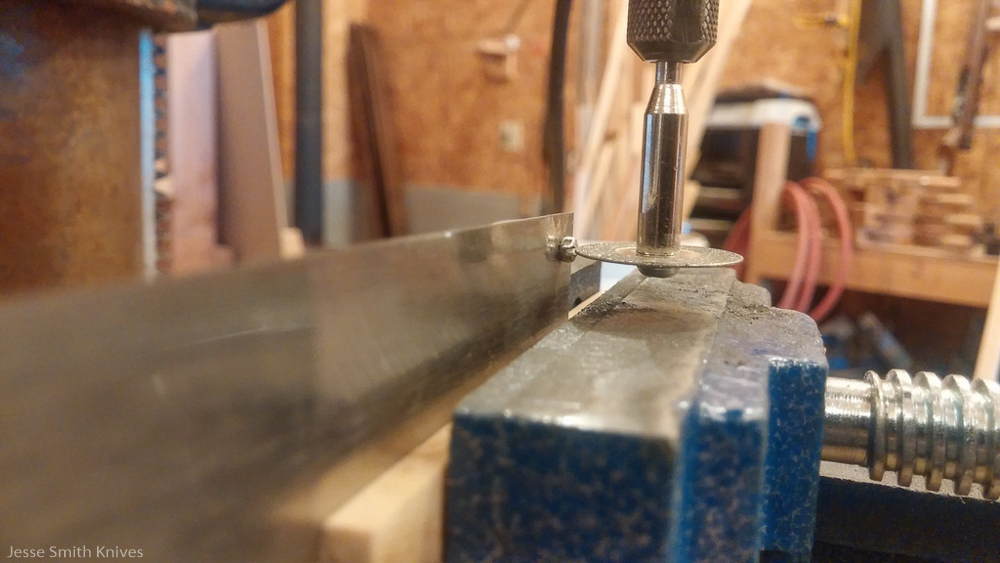

Here's the rest of the drill press. It turns out the table arm is just the right size to lightly clamp my Dremel in place, and with a diamond wheel and POS Harbor Freight drill press vise, it makes a handy way to cut liners...

Or to slot screws...

Also, if you remove the Dremel and place a piece of 1/4" steel across the table arm, you can put a rivet tool in the chuck (with a short piece of 1/4" round above it, so it doesn't slip) and it makes a great press for setting rivets on Kydex.

And of course no knife shop is complete without a port-a-band turned redneck scroll saw. I broke with tradition and cut the blade slot on the table, behind the blade. I just didn't want a groove in front of the blade for the edge of parts to catch on...

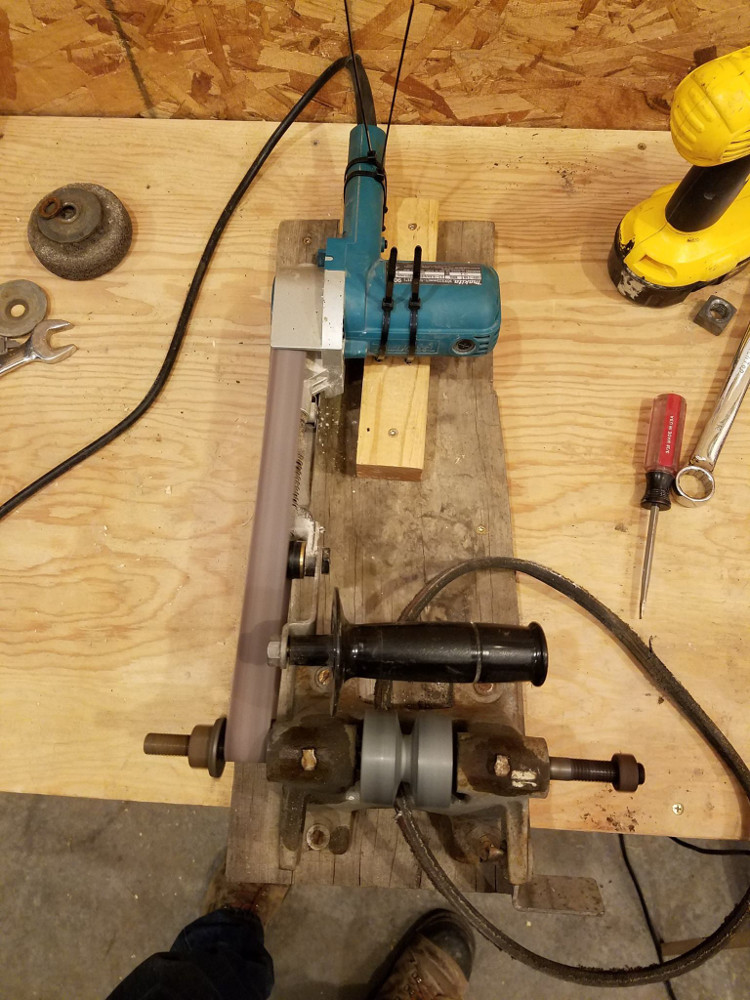

Oh, and just for laughs, here is my small wheel grinder. Hahaha. Seriously though, until I could afford my 2x72 I got by with a 1x30 Harbor Freight grinder, but wasted a ridiculous amount of hours trying to clean up inside curves by hand with sandpaper rolled around a socket extension. This setup may have used parts two or three times my age, and it may have vibrated things of the wall of my shop, but it turned a two hour hand sanding job into 5 minutes...

Well thanks for looking. Maybe these will inspire someone to find a use for something they have sitting around. And if anyone has any suggestions for improvements, the small wheel grinder is the only tool I don't still use. So I'm open to improvements.