The topic for February will be small tools and jigs. It has been a while since we did a thread on this, and we thought it might be time to revisit the topic since we have new members on the forum and in the ABS.

What little things do you have that make knifemaking easier around the shop. Things such as special jigs, special tools, etc. Pictures would be great, just remember to keep them in size.

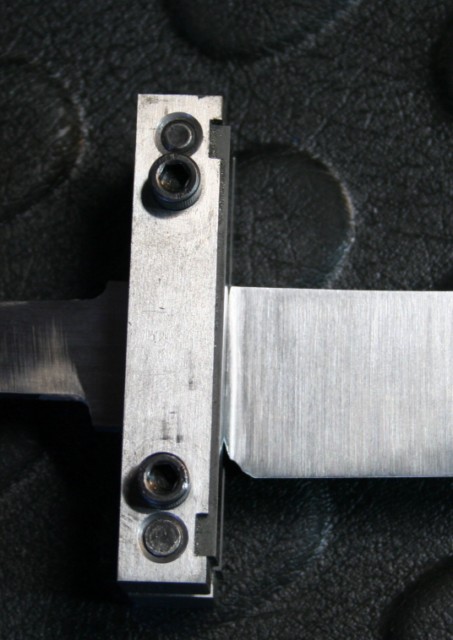

One not so special tool I can not live without is a shoulder filing jig. I made my first one. It was the definition of ugly. I now have three of them. The one I use the most is one with carbide faces. You can use them for filing shoulders, filing plunge cuts, filing clips, and as a stop for filing thumb notches on a spine.

So many uses.

Another tool is the needle file, specifically diamond needle files. They come in real handy for cleaning up plunge cut areas after heat treating, also on clips in the hardened area of a knife. Again one of the must haves for me.There are some others I will probably think of and will post later on.

So what do you all use? and what makes things easier for you?

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Mastersmith Hanford Miller demonstrating his Leveling Table Jig- ABS YouTube Video

Mastersmith Hanford Miller demonstrated the use of his Leveling Table Jig at the ABS Hammer-In in Dubois, Wyoming in July 2008 which was the Silver Anniverary of the first ABS Hammer-In which was also held in Dubois, Wyoming. Hanford Miller has been a Mastersmith in the American Bladesmith Society since 1986. This video clip was filmed during Mastersmith Miller’s presentation on "Knife Jigs and Fixtures".

CLICK the arrow sign to view the video clip below.

[media] http://www.youtube.com/watch?v=K1miCYvopxI&sns=em [/media]

Dan Cassidy

Journeyman Smith

Send an email to Dan

I've talked about this with some members, but I'm a huge fan of the Grobet Valtitan files, needle or otherwise, since you mentioned files. They're spendy, but at 72 RC hardness, they'll easily cut hardened steel. Really nice for changes and fixes post HT, where you can't soften an area, but are afraid to go to the grinder for tiny work, but with the same action as a regular file, versus a diamond file.

I've got two sets of the needles, and a few of the hand files. Really dig em, especially in the courser cuts.

I love my carbide faced filing jig, that came from Bruce Bump's shop. Last I heard he was offering them in stainless too, which is very nice, and I plan to get another when I can afford it.

How far do we want to go with this topic? <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//wink.gi f' class='bbc_emoticon' alt=';)' />

Granite surface plate, height gage, and 1-2-3 blocks are one of the most used "aids" on a daily basis in my shop, I couldn't live without. I'm sure most of us have them by now, but if you don't a real B-grade surface plate is too cheap not to have one, and can aid you in everything you do in the shop, even beyond knife making. Every investment I've made in measuring tools has been well rewarded. I keep a pair of ebay dial calipers ($15 mitutoyos but worn out), laying around in the shop to abuse, but a good pair of digitals, inside. IP67 tools are coolant and dust proof, a big bonus for use around grinders and such, just like the Nema 4x VFD's we use.

I believe one of the things that really excels the modern maker's potential, compared to hundreds of years ago, isn't in the machine tools we can use to make many processes less tedious, but in the advancements metrology technology, that make for instance, reading to the thousandth, trivial.

What about tool rests or grinding jigs? I can't hang onto a blade very well when flat grinding without a tool rest personally. I'm sure it comes with more practice, but usually they get ripped out of my hand. I do ok with a wheel or slack belt. Anybody use a hollow grinding jig?

For the final step in sharpening a knife, I use a leather strop that I made out of 3/4" thick and 5" wide x 12'' long red oak with an ample tapered handle at the end. I glued on leather to cover each side. On one side I apply a mixture of red rouge and olive oil and the other I apply a mixture of green chrome and olive oil. This is a photo of my strop below.

I used a simiar but smaller strop to sharpen my straight razor when I was working as a Master Barber years ago. I was told by Master Smith Jack Fuller who was trained in Bill Moran's shop that Master Smith Moran would use a similar strop as the final step in sharpening his knives and that he would work on the knife until it was very sharp.

Dan Cassidy

Journeyman Smith

Send an email to Dan

I took a Slip Joint Folding Knife class at Haywood Community College, Clyde, North Carolina in December 2012 from Master Smith and instructor Steve Dunn. Every student in the class built and took home a finished slip joint folder in their pocket. We used and learned about some new tools to build pocket knives that have applications for building other knives as well in the shop.

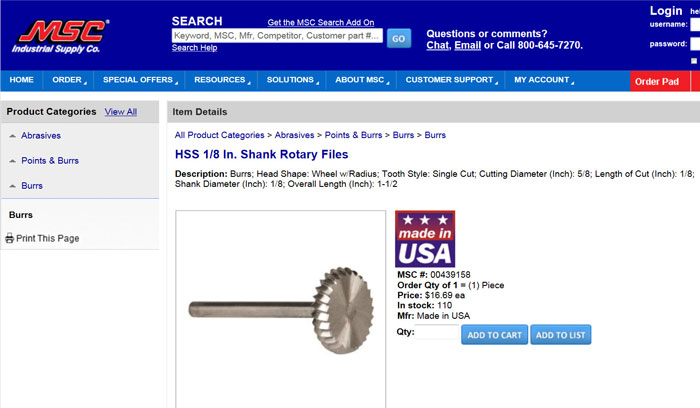

Steve Dunn used a jigging cutter in a Dremmel during his demonstration on "Jigging and Shaping Knife Handle Scales" which is a video on the ABS YouTube Channel. The jigging cutter is an HHS 1/8" shank rotary cutter that can be found at, Click: MSC #00439158.

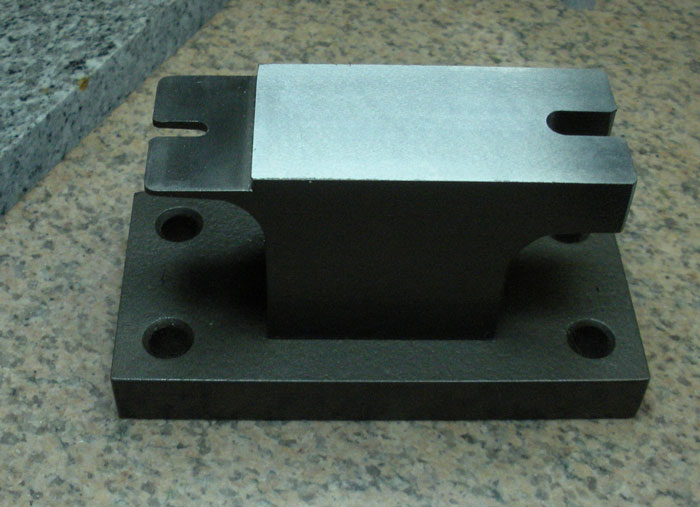

We used the "stiddy" that Steve Dunn had on his work table and found it to be very useful. This small anvil was so useful that I searched for one immediately after the class and located one on Ebay that had been made by a machinist. This is a photo of it on my work bench.

I also learned about a holding device to use when grinding the blade for a folder. It works very well and has many additional uses to hold small parts for grinding or filing. I located the "Kirkland Ring Clamp" on Amazon.com at, Click: Kirkland Ring Clamp This is a photo of it below.

Dan Cassidy

Journeyman Smith

Send an email to Dan

Dan, I can see those tools having real value sitting on your workbench!

I was forging a blade yesterday evening and discovered that tarp strap hooks make an excellent lock for your tong handles.

A slight modification might be nessasary. To adjust your hold on your stock, slide the hook down the handles and reset.

Works great!

Russell

Here's one I have not use for a year or so, but should put back into use one of these days!

It is very handy for those wanting to do some wire inlay.

Rather than go 'round and 'round your self, <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//blink.gi f' class='bbc_emoticon' alt=':blink:' /> it's easy to turn the knife instead.

Just a cut off bowling ball, small mill vise and a rubber tire:

Karl B. Andersen

Journeyman Smith

This is a little holding jig I saw somewhere. Square tubing and some hardware store pieces. It allows the piece to be away from the vise and holds real well.

Hey guys,

Thanks for sharing all of these! Great stuff!

I made this narrow tang Press out of things laying around the shop. It holds my handle and blade assembley together while the epoxy dries. The knife in the photo is just to show how it works. I have two of these, one is 12" long and the other 22" long.

Here are some other things I could not live without. Javan mentioned the Valitan files, which are available through RioGrande Jewelry supply. RioGrande

Another handy tool is the third hand. Much like Dans jewelry clamp.

And another little device from Al at Riverside. Did you ever try to hold an oval bowie guard to clean up the faces, kind of tough to do with a grinder or by hand. Well this little device makes thing much easier, allowing you to clamp the guard up and be able to hold on to it or clamp it in a vise.

brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Good stuff so far. This is a little trick that I use to drill holes to exact depths. While you can set up your drill press stop, it has to be setup everytime a piece is moved or a mating piece needs to be drilled. With this method, every hole will be the same depth until the drill bit is removed from the chuck.

I came up with this when I had to drill customer provided ivory slabs. The knife needed blind holes drilled into the ivory and I needed to make sure I did not drill through. With this method, you cannot drill too deep.

This method is really pretty simple -- just insert the drill bit into the chuck and only allow the drill bit to stick out as far as the hole is to be deep. I measure with a calipers. Then simply drill the hole until the chuck jaws touch the work.

Here are a couple gadgets I use in the shop regularly.

First is my "Damascus Horse" that I use for welding and grinding billets during the pattern welding process.

I also use it frequently in the general process of welding.

Of course, it's all steel, so I can just clamp the ground lead anywhere. Then I can use either the vise or the C-clamp - which are attached on either end - to hold whatever work piece is under construction:

The other is my Brute de Forge station where I can roll this 350 pounder around the shop right next to my forge. And then roll out of the way when not needed.

Heavy post vise for forging in the choil.

90 pound (means weight per foot) rail topped with a big block of steel for setting the choil and forging the rest of the knife.

It has been invaluable to me in other needs as well when I simply need another "hand" that is sturdy and won't move!

Karl B. Andersen

Journeyman Smith

Karl,I see a heat treat tanks behind the vise and anvil post. If you don't mind, would you share the dimensions, volume (i.e., quarts/gallons)and gauge steel? It would be helpful to apprentices, so we can construct a tank that will provide proper quenching/heat transfer. Thanks in advance!

Bob

Robert, that looks like a bluing tank to me. Karl can fill us in. I use a bluing tank that came from Brownells. The dimensions are 6"x6"x48" and it holds five gallons of quenchant. I think they run like $60.00. Works great. I bet Karl has added some extras to his.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith