Hey,

I'm sorry I post a lot in tools. Seems to be the largest learning curve for a new knifemaker <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

So I went through the whole "need a mill" phase. I was about to buy a new $1500 mill/drill, when I realized that I could find a decent knee mill if I was patient. So I went that route instead, and though it takes up a lot of room in the shop, I couldn't be happier that I did.

Now I'm looking for a lathe. However, room is a PREMIUM at this point. I'm frankly running out.

So instead of buying an old 10-12 inch lathe from craigslist or whatever, how about the newer 8 inch precision mini-lathes? Will it do everything I need to for knifemaking? I'm looking to try building a takedown in the near future, but machining some of the parts looks like it's way easier on a lathe. The used lathes that pop up are usually about $1200, but look like garbage, or they're like $2-4k which is beyond what I'm looking to spend right now.

The one I'm looking at is an 8x12, 3/4 hp, 4 inch lathe chuck, 3/4 inch capacity. I think it's 150-2500rpm in 6 speeds. $800+tax

Can you post a link to the lathe you're looking at? That way I could take a look at it and give you my thoughts.

I've owned two of the Grizzly Mini lathes, and neither lasted more then a year before I had to start replacing parts....namely the electronics/boards. After that I purchased a Grizzly G4000, which is a 9x19 lathe. It held up great for about 3 years, and just recently I've had to replace several parts on it. I've come to the conclusion that just about any of the modern equipment, at least until you get into the really high end stuff, is basically made to last for a couple of years, then be a "throw away".

In your case, it sounds like a priority is size, because of a space shortage...... my usual advice to folks looking for machines is this... you can always do small work on a larger machine, but it's impossible to do large work on a small machine. That being said, I would consider the largest projects you every think you might do....then find a lathe slightly larger then that (we always underestimate the largest work we ever intend to do on any given machine) <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

I think I'm leaning towards a grizzly:

http://www.grizzly.com/products/8-x-16-Variable-Speed-Lathe/G0768

http://www.grizzly.com/products/9-x-19-Bench-Lathe/G4000

http://www.grizzly.com/products/10-x-22-Bench-Top-Metal-Lathe/G0602

The harbor freight one I'm looking at is this one, and for once HF is the more expensive of its competitors, but that 20% coupon goes a long way.

http://www.harborfreight.com/8-inch-x-12-inch-precision-benchtop-lathe-44859.html

I'm a little gunshy with grizzly. HF you know what you're getting, but they are like Wal Mart, you show up with a box of rocks and they'll just exchange it. Grizzly, I'd have to ship the thing back. And more than half youtube videos I see of grizzly stuff people say they come out of the box with stuff broken or misaligned.

I want to be able to make fittings for knives. I probably want to be able to make little parts to maintain tools. Every time I lose a pin or something I go "I could just make one of those on a lathe if I had one". And maybe I'd like to learn how to make my own cutting tools for the mill some day. And maybe even my own damascus jewelry or something.

I'm VERY gunshy of HF, just like you are of Grizzly. I was really frustrated with Grizzly when my G4000 went down. I order replacement parts, and they were so far out of spec that they simply where not usable. I let Grizzly know about it, along with pics and specs of the parts they'd sent, and it took them two months to get me another set of parts.....that were just as far out of spec/unusable as the first. I ended up going to a friend's shop and actually building the parts I needed from scratch. So the next time this G4000 goes down, I'm just gona consider it a "throw away" and get another lathe. I've actually been thinking of the G0602, because it has a 1" bore versus the 3/4"(actually 20mm) on the G4000. For me it's all about how much money any given machine makes for me, and in the case of the G4000, it's produced at least 500 Damascus pens....so it's paid for itself.

I was all distraught about the G4000 going down, but a friend made the point of how many pens I'd produced with it.....and told me to quit whining, that it had paid for itself, and just get another one....and use it util it wears out. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

I wish I could say something good about the HF lathe..... everybody that I know who's purchased one has had to return it at least once, and most are sorry they bought it. I've always consider almost anything HF as "one use and throw it away" type tools.

I guess it all boils down to what YOU are comfortable with. Where it me, I would go with the G0602.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

Nicholas

I have had very good service from my Grizzly machines, but my machines are the full size models.

You might look at the Smithy machines. My first machine was a Smithy combo drill- mill- lathe. I

still have that machine and it still runs perfect after about 20 years, the only repairs were a

run capacitor, and a power switch. The machine was small but I did a lot of work with it. Making

small parts for firearms,and other needs. It was just to small for any real barrel work.

I know you are concerned about size and the Smithy was very compact. It might be what your looking

for. Hope this helps some.

Anthony

I had a 14" hendly for years, never used it, i passed it along and now have two southbend 9" I have not found them to limit what i can do other than a few Iron work jobs and machine repairs, for knives they have done everything I wanted them to.

I found a Logan 820 on craigslist for $1250 with an 8 piece collet set and a couple extra chucks and tools. There's probably an extra $400 in tooling with it that I wouldn't get with a new one. Which is good because I'm probably going to need to rent a trailer. It's also a 3-4 hour drive :/

I'm considering the Grizzly G0768 and the G0602. Either save some space, or get a bit more of a machine for another $200.

Anyone familiar with the Logan? It has cross slide feed, and from what I understand they're somewhere between an old south bend and an atlast as far as quality and features.

It does seem like all of the issues are maintainable, but it worries me they obviously never check anything to see if it's even functional. Hard to beat the price though. https://www.youtube.com/watch?v=WNZOYcL4nVQ

I missed out on the logan. Kinda kicking myself for that.

Is this a steal for a south bend lathe? Grizzly has the new South Bend 10k on sale right now for $3100. I'm trying to figure out which kidney I like the least.

Nicholas,

When it comes to tools, you normally get just what you pay for. One time while visiting the Grizzly store I had the chance to visit with a factory rep who informed me that there are only three tool manufacturers in Taiwan and each makes five grades of tools. Harbor Freight usually buys the bottom grade. Grizzly will usually buy medium grade or better tools. If you buy Grizzly's industrial grade tools they're pretty good but still not what industrial grade American tools will be. In the long run you will get better performance with a used industrial grade American tool than with a new Chinese one.

Just my $.02

Gary

|quoted:

Nicholas,

When it comes to tools, you normally get just what you pay for. One time while visiting the Grizzly store I had the chance to visit with a factory rep who informed me that there are only three tool manufacturers in Taiwan and each makes five grades of tools. Harbor Freight usually buys the bottom grade. Grizzly will usually buy medium grade or better tools. If you buy Grizzly's industrial grade tools they're pretty good but still not what industrial grade American tools will be. In the long run you will get better performance with a used industrial grade American tool than with a new Chinese one.

Just my $.02

Gary

I agree. If I go Grizzly it'll be G0602, simply because if I'm going to pay more than that, I can get a used old American lathe. But I think I'm going to be patient and wait for an old lathe to pop on craigslist. There's a few now, but I'm really leaning towards a nice 10 inch. The one I shared above is a new South Bend 10k for $3100. And they only charge $150 to ship... so that almost pays for itself. I remember paying something like $800 for my knee mill get get to my door.

I kind of wish there was a machine shop in the area I could just rent time on. I wouldn't mind paying $50 to use a lathe for an afternoon. I don't plan on using one every day, just occasional use for some projects and maybe start making pommels and stuff like that.

The other problem buying lathes locally, is there's a few HUGE ones for like $1500, but I just don't have room for them. There's a Monarch for $1500 the guy said it's 11 feet long haha.

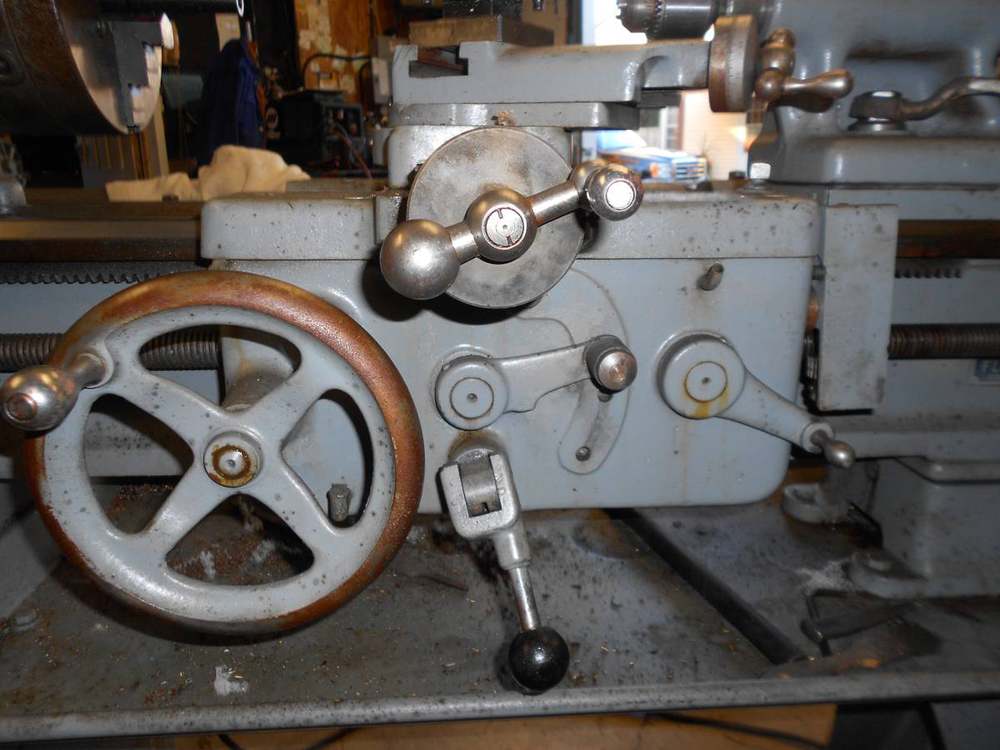

Hey I found a lathe about 2 hours away that looks pretty promising.

Do any of your machine gurus have and advice on this one?

It's a South Bend Heavy 13 with hardened ways and looks like the 2 speed motor. Owner claims it comes a taper attachment, 3jaw chuck, 4jaw chuck, collet rack, live center ,two drill chucks and tool post. When I talked to him it sounded like he was going to try to see if he had the steady and follow rest for it and some dead centers. It's a new enough model to have the lever clutch. The serial number indicates it's probably late 1970's I think.

Let me know what you think. I appreciate the advise.