Hi,

I have a single to 3 phase VFD, and a 3 phase motor. I want to be able to use the VFD on this 2x72, and also move it over to an old knee mill that I just bought. So I want to wire it up with jacks.

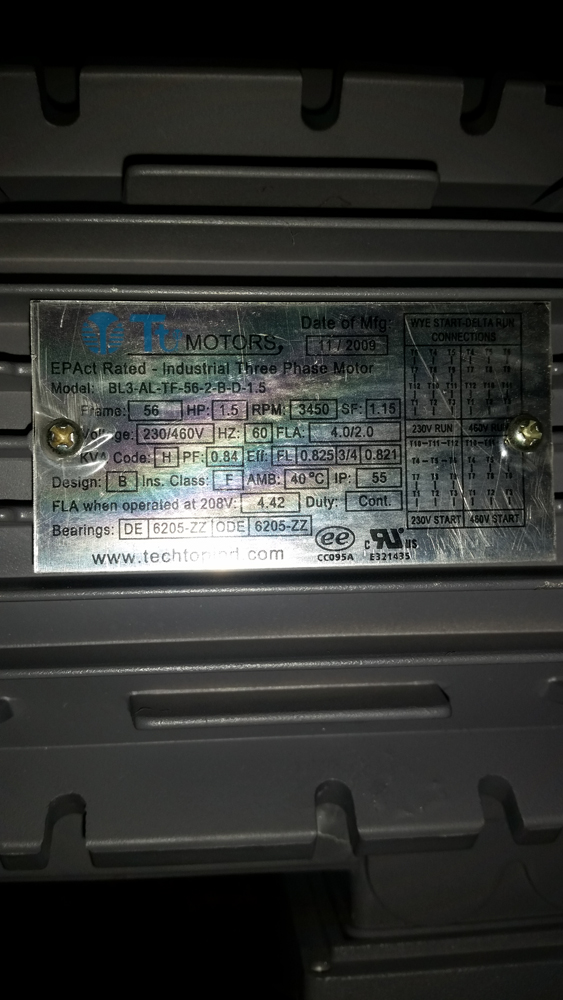

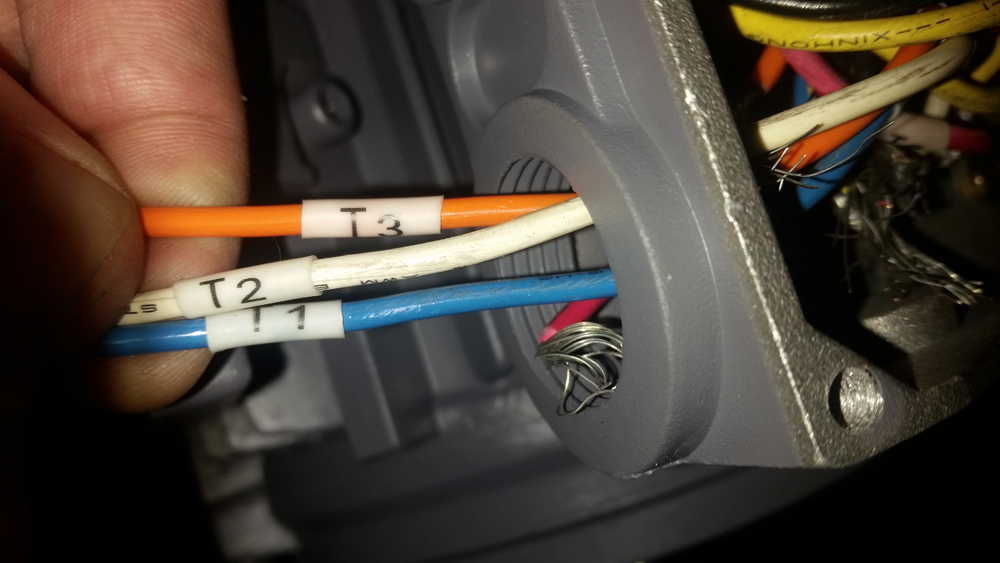

I don't understand where the wiring needs to go in the jacks for it to work. I'm confused why the VFD only needs 2 in and 3 out when I'm pretty sure I saw the dude connect 4 wires to the milling machine when he hooked it up for me to check out. Doesn't it need to be grounded somehow? Is wiring the motor as simple as getting T1, T2, and T3 to its respective jack on the VFD? The wires in the motor aren't isolated. Is it ok If they're just stuffed back in there box, or am I supposed to cap them off first?

I am willing to make a new extension chord if I have to.

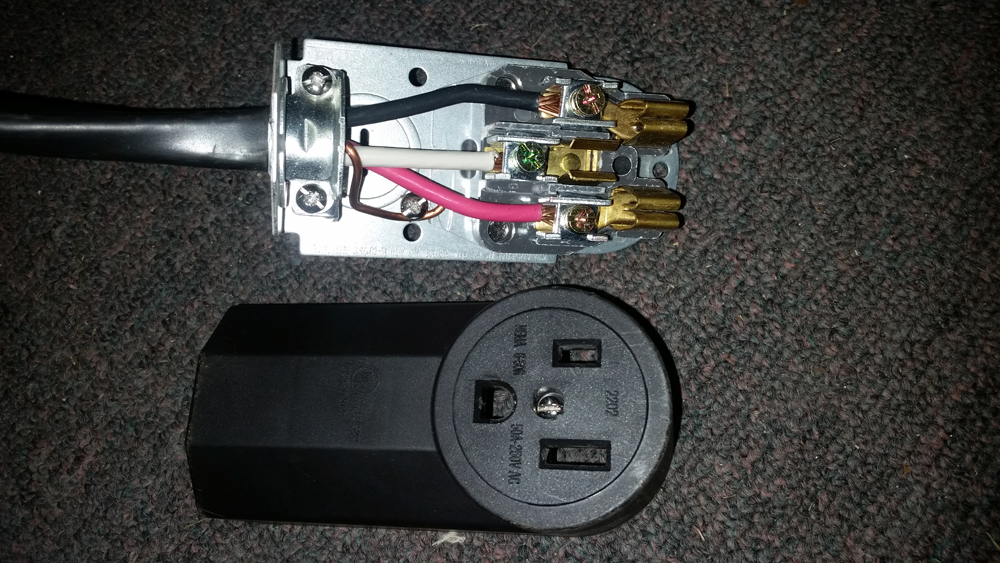

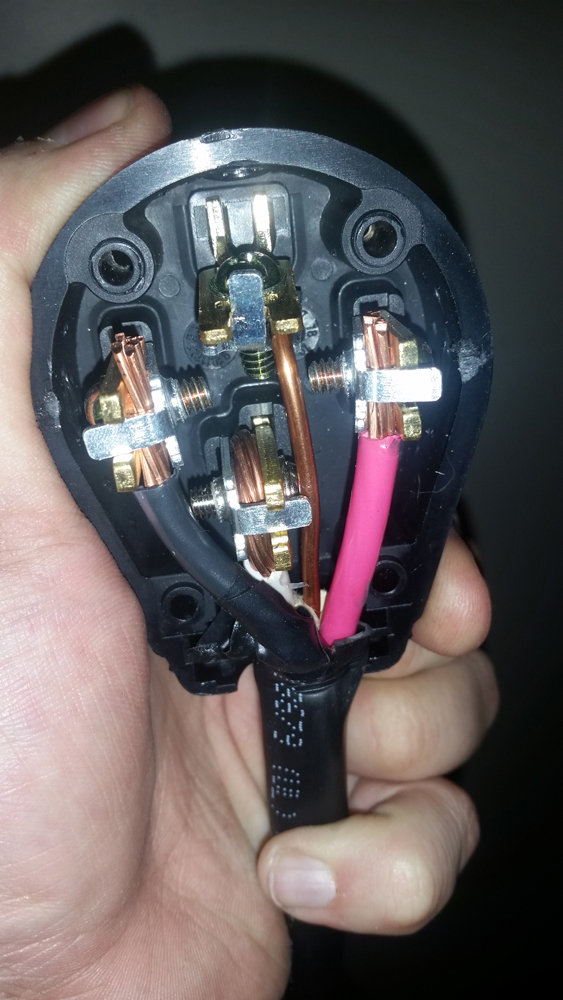

The extension chord I have for my MIG welder goes to a 220 in another room. It goes from 4 pin to 3 pin as shown in these photos:

The motor, VFD, and jacks that I bought are here:

Your help is much appreciated.

Thanks,

Nick

Don't worry over two in/ three out on the VFD. The little yahootie in the box pushes all the right buttons.

Three phase motors need three lines and a ground to your devises.

Don't confuse 240 single phase with ground as three phase; they are not the same.

If all this confuses you buy an electrical friend a beer to hook it up; much cheaper than a new VFD.

M

Mike Williams

Master Smith

Take a look at this page on my website about hooking two motors to a single VFD, it MIGHT be helpful: http://www.caffreyknives.net/1_VFD_2_Motors.html

I've got to warn you, I've used those TECO VFDs in the past, and had nothing but problems with them. I had endless issues, and finally got rid of them and went to KBAC VFDs..... one of the best moves I've ever made. Since moving to the KBAC VFDs, it's basically wire it up, and forget it.

I can't tell much about that VFD from the pics, but also feel it's worth mentioning that you need to ensure the VFD is rated for the largest HP motor you're running, and IF you are running two motors off a single VFD, it's vital that you ALWAYS allow one motor to COMPLETELY shut down before switching the power....otherwise you will burn out capacitors in the VFD..... no matter what brand/variety is might be.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

I figured it out. It took way more time than I wanted, but she's all wired up and seems to be running fine. The motor unfortunately didn't fit my 2x72. The wire housing interferes with the frame. But I think it shouldn't be too hard to modify and make it fit.

I'll show some photos when I get her into the 2x72.

I don't plan on running 2 machines at the same time, but I wanted to set it up with jacks so I could move it to the milling machine when I wanted to.

What issues did you have the TECO? I haven't been through the settings menu yet, but I was able to set to a specific frequency and it would ramp up or down. I'd rather use the dial, but it doesn't do anything. I assume I gotta set something up in the menus.

the settings menu yet, but I was able to set to a specific frequency and it would ramp up or down. I'd rather use the dial

That's part of the reason I dislike the Teco units....they are just a "time eater" to use, no matter what you want to do. It's difficult to explain, but they are just nowhere near as user friendly, nor as trouble free as the KBAC controllers.

Much of my dislike for the Teco units is experience based..... I've spent a great deal of time on the phone and/or via email with individuals who have issues with the Teco units, and are seeking my help. Also, on many occasions I've had students in my shop who have the Teco units in there own shop(s), and they make comments about how easy the KBAC units I have are to use/deal with then the Teco units they use. Many of those same individuals went back home and switched to KBAC controllers, and tell me they eliminated all their issues.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

Well it ran fine for a little while, then I autotuned it, and it exploded. I'm 100% sure I put in the right parameters for the autotune.

I hope they let me exchange it..

Crud! Sorry it happened like that!

If they will warranty it.....try to get your money back and see about a KBAC 24D, 27D, or 29D (whichever one is rated for your motor hp.) I started to mentioned something about the autotune causing self implosion on the Teco units, but thought it would sound like bashing....wish I would have done it now.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

Have you heard anything about that? Is that a common problem?

The default settings were 1715 RPM, 220V, and 1.5KW, and 6.1 amps. I changed those to 3450RPM, 230V, 1.1KW (1.5HP equivalent), and 4 amps per the label on the motor.

There's a KBAC on ebay that's a NEMA 4 enclosure. I've got my eye on that if they don't honor the warranty. I did have an electrician check this out today, so I'm confident it was wired properly.

Just in case it's some kind of dust issue (even though I haven't even used it yet..) I'm going to make sure it's mounted farther from the grinder.

I just hope it didn't hurt the motor... then I'm really out of a big buy.

Unfortunately yes.... I've heard of several people who had the same thing happen to them with the Teco units.

Make sure you are looking at the correct KBAC for your motor hp. Personally I won't buy a controller off ebay....ya don't know where it's been, or how it's been treated.

Here's where I buy all of my motors and controllers: http://www.electricmotorwholesale.com/DRIVES-KBAC-NEMA4X.html

For a 1.5hp you'll need a model 27D. Also pay special attention to the input power source (match it to what you have in your shop) and the output amps. Make sure the output meets or exceeds what's on the motor info plate of the motor you'll be using.

Just for informational purposes, here are links to..

The motors that I use: http://www.electricmotorwholesale.com/LEESON-116107/

And the controller(s) I use: http://www.electricmotorwholesale.com/10001-KBAC-29D/

Just like motors, all VFDs are NOT created equal....you'll spend more for a KBAC in the NEMA housing, but once wired correctly, they are far more durable and trouble free then any other brand/type I've seen.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

So weird. That sounds like it's their fault. I didn't have any dust, so I doubt that's the issue. I guess it could have been, but the failure sounded distinctly like an exploding capacitor. I hadn't actually ground anything yet, I was just getting the motor in place and getting the tracking correct.

Someone in another forum mentioned that the caps should be "conditioned" by putting power to the VFD for an hour before running it the first time if the VFD has sat on the shelf longer than a year.

Not sure. Obviously since it's a holiday weeknd, I probably won't hear anything from them until Tuesday...

They will replace it. TECO's customer service is a little disappointing. I convinced the supplier to send me a replacement, but TECO wanted me to mail it Texas myself, examine it, do a warranty authorization, blah blah blah. It would have taken over 2 weeks.

So I won't be running the optimization algorithm then...

If I want to hook this up to my Mill, do I just leave the mill always "on" and start and stop it with the VFD? I see some recommendations to bypass the junction box and only wire the VFD directly to the motor. Any experience with that?