Zach

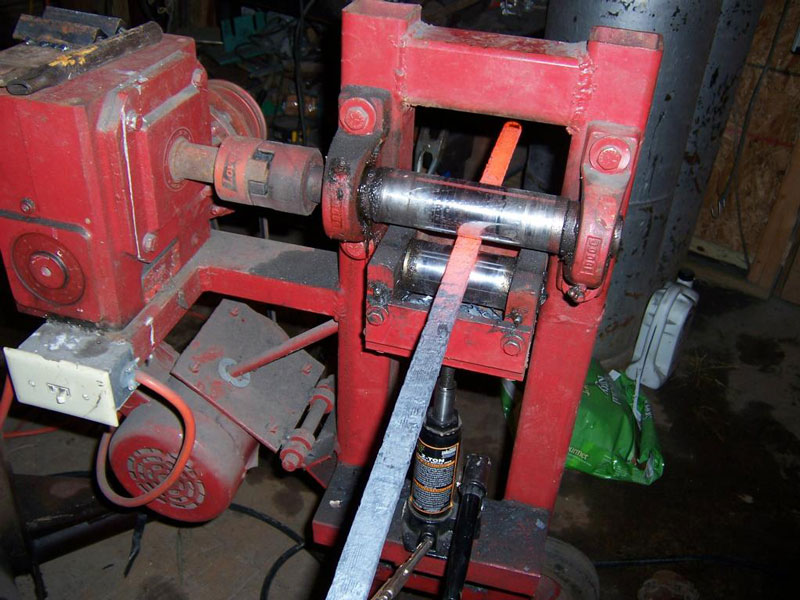

This is a picture of my rolling mill.

This is a simple model with just the top roller being driven. The top roller turns in bearings and the lower roller is in bushings.

Rolling mills are a great tool and will do some very nice work leaving smooth finishes. There is a drawback to them when making Damascus though. Because they are so good at what they do, they offer little distortion to the billet which can make for an uninteresting pattern and some patterns just do not work in a rolling mill. I once tried to make a W pattern in mine and to put it simply, it will not crush the billet so you do not get any W's.

Where the mill really works well is in drawing out bars of steel and making billets smooth and an even thickness. I also find that my mill tends to move the steel down the length of the bar keeping the bar pretty much the same width and just making it longer. The mill combined with my press make for a very nice combination.

Another thing that is really cool that you can do with a rolling mill is to forge your blade bevels first with no distal taper. Just let the blade curve around as you form the bevels. You cna then run the blade through the rolling mill and keep closing the rollers as the blade passes though. By doing this, you will "roll" in the distal taper and straighten the blade at the same time. It takes a little practice, but is very effective when you get the hang of it.

Brian

Very interesting thread guys. I'm planning a mill for my shop. So, I'm interested in this information. Not much out there on rolling mills. Brian, I would like to see a larger picture of your mill and/or more photos of it. Let me know if you need help with larger images.

Thank you guys so much. honestly what i want to get into in making San Mai style blades with 15n20-1084-15n20. Set the weld with the roller, draw it out to 1/4 inch, then hammer it as normal.

and eventually when i save enough for a press or hammer be able to provide the proper distortion or whatever to make a proper crushed w pattern for the damascus patterns i want.

HEY! so i am also pushing for linking to imgur.com if you have high res pictures since you can't post them directly on here. you can post pretty much as big as you want and its free. and pretty light weight.

just so we can see what you are talking about closer. right now the pics i'm seeing are super tiny small i need glasses for my glasses <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//tongue.gi f' class='bbc_emoticon' alt=':P' />

anyways. i have always wanted a rolling mill, even before blade smithing. my dad worked at a steel mill for years and i got to see the "hot strip" as they called it. vehicle size blocks fo steel drawn out to less than 1/4 inch thick and wound up into coils. so amazing. all in a single heat <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//wink.gi f' class='bbc_emoticon' alt=';)' />

basically this is what i want to build... looks super simple. Look its DEE!...

oh and it starts showing it around 1:20...

Zach

San Mai is a perfect fit for a rolling mill! It is very helpful for keeping the core centered. It is a good practice when doing San Mai to flip the billet over with each pass when doing San Mai.

As far as the Damascus goes, I was not trying to discourage you, but rather save you finding out the same things that I discovered the hard way.

My Mill is very similar to Hank's mill in your Youtube. Hank's is built like the Hugh McDonald type. The main difference to mine is the way the rollers are closed.

Sorry for the small photo, I will try to post a larger one tonight.

Brian

|quoted:

Zach

San Mai is a perfect fit for a rolling mill! It is very helpful for keeping the core centered. It is a good practice when doing San Mai to flip the billet over with each pass when doing San Mai.

As far as the Damascus goes, I was not trying to discourage you, but rather save you finding out the same things that I discovered the hard way.

My Mill is very similar to Hank's mill in your Youtube. Hank's is built like the Hugh McDonald type. The main difference to mine is the way the rollers are closed.

Sorry for the small photo, I will try to post a larger one tonight.

Brian

do you have plans to any of these mills? currently i'm going off of what it should be in my head.

|quoted:

do you have plans to any of these mills? currently i'm going off of what it should be in my head.

Check out this link and the subsequent links there for a lot of info: http://forums.dfoggknives.com/index.php?showtopic=13865

|quoted:

Check out this link and the subsequent links there for a lot of info: http://forums.dfoggk...showtopic=13865

thanks a bunch. that looks a lot like what i had in mind, with a couple changes.

Sorry for the delay in my response, I have been fighting some computer issues.

This is a larger photo of my rolling mill. It has a 30:1 reducer that is driven 2:1 with a belt to give a 60:1 reduction. This was built from scrap with things that I was able to aquire. My main goal when building this was simplicity. I pump the jack closed rather than make up a complicated foot lever system. I just msde a shelf for the jack to set on. There are advantages to the foot lever and advantages to the jack.

The nice thing about the gear reducer is that you do not have all the moving parts that have to be aligned and guarded.

Brian

Brian,

Great photo! And a well thought out, and applied idea.

Thanks for sharing it with us.

Russell

|quoted:

Sorry for the delay in my response, I have been fighting some computer issues.

This is a larger photo of my rolling mill. It has a 30:1 reducer that is driven 2:1 with a belt to give a 60:1 reduction. This was built from scrap with things that I was able to aquire. My main goal when building this was simplicity. I pump the jack closed rather than make up a complicated foot lever system. I just msde a shelf for the jack to set on. There are advantages to the foot lever and advantages to the jack.

The nice thing about the gear reducer is that you do not have all the moving parts that have to be aligned and guarded.

Brian

so the big box above the switch is a reducer? never heard of one. any helpful info about buying one? expensive? certain things to look for?

Basically i would love to build what you have there. maybe later on upgrade it to a pedal, but i basically only need it to set welds for me right now. i think 168" per minute would be just fine. and using the chromed hydraulic cylinder rods.. brilliant. i know a place where i can pick those up cheap. i even have a chop saw that will cut those to length for me. how did you attach the drive roller to the motor? and also both of the rollers to the bearings. it looks like you have another bar of metal running through it? i don't know much about construction of this sort. but here i am asking. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//biggrin.gi f' class='bbc_emoticon' alt=':D' />

Yes that is a the reducer above the switch. You need somewhere around 60:1 reduction and yes these are expensive. I was able to get this one out of a scrap hopper. Do some searching on ebay and SurplusCenter.com. Remember to get one that will handle your input horsepower.

The rollers are turned down on each end to 1 3/8" for the bearings and the drive end has a keyway in it for the LoveJoy coupler.

The bottom roller is also turned down on both ends and runs in bushings and sets in a box made from 1" steel. It has a 3/4 rod hinge in the back so it can move up and down.

Brian

|quoted:

Yes that is a the reducer above the switch. You need somewhere around 60:1 reduction and yes these are expensive. I was able to get this one out of a scrap hopper. Do some searching on ebay and SurplusCenter.com. Remember to get one that will handle your input horsepower.

The rollers are turned down on each end to 1 3/8" for the bearings and the drive end has a keyway in it for the LoveJoy coupler.

The bottom roller is also turned down on both ends and runs in bushings and sets in a box made from 1" steel. It has a 3/4 rod hinge in the back so it can move up and down.

Brian

30:1 Reducer This should work if i ran it off a 1 HP motor, right? if i understand it correctly i can use UP TO a 1.2 HP. it doesn't have to be 1.2, just no more. and it would be about 150 bucks after shipping. i'm guessing the only 2 "expensive" parts will be the reducer and motor. the rest seems like stock material. and if i find it going a little faster i just have to change out the pulleys. instead a 2:1, i could use a 2.5:1 or whatever. especially if i decide to use larger rollers.

and i thought i was going to have to get heavier framing for it, but in your picture it looks like you are using simple steel tube framing. which is great because there is a company that makes and sells that stuff super cheap close by i just found out.

Zach

I do not think that the reducer you linked to would hold up. My reducer is 30:1 with an input rating of 2.75 HP and an output of 2415 inch pounds of torque(this number is important. It tells how much force the output shaft can take. after that, something stops or breaks.). Remember that I am belt driving at a 2:1 ratio so you multiply the ratios to get 60:1. with a 1750 RPM motor, it gives me around 28 RPMs for the rollers.

The reducer you linked to is rated for 1.2 HP so if you used a 1HP motor and belt drove it at 2:1, the reducer would actually see 2 HP.

I am using a 1HP motor and have worked the mill pretty hard. The reducer has gotten pretty hot from the work I was asking of it which tells me I am working it beyond what it was intended to do.

The reducer that you are looking at would work, the question is how long. A better choice is this one 60:1 reducer.

This gets you the output RPM you need, has enough torque output to handle what you throw at it, and can be direct coupled to a motor or belt driven at a 1:1 ratio. There is also a 30:1 reducer with similar capabilities ans also the same price.

One thing that I always look at when buying something that I want to only buy once is the shipping weight. The weight of the stronger reducers is double of the other one. This tells me that it is built of heavier components that are not as likely to fail.

You are correct about the tubing, it is 2 1/2" square tubing with 3/16" wall thickness. This stuff was scrap that I picked up. as a matter of fact, I did not have enough long pieces and had to weld pieces together to get the length I needed. If you are buying the steel, I would go with 1/4" wall thickness.

Remember my previous posts about roller size. when you go with bigger rollers, you require more torque and more reduction to keep the feed at a managable speed.

Brian

|quoted:

Zach

I do not think that the reducer you linked to would hold up. My reducer is 30:1 with an input rating of 2.75 HP and an output of 2415 inch pounds of torque(this number is important. It tells how much force the output shaft can take. after that, something stops or breaks.). Remember that I am belt driving at a 2:1 ratio so you multiply the ratios to get 60:1. with a 1750 RPM motor, it gives me around 28 RPMs for the rollers.

The reducer you linked to is rated for 1.2 HP so if you used a 1HP motor and belt drove it at 2:1, the reducer would actually see 2 HP.

I am using a 1HP motor and have worked the mill pretty hard. The reducer has gotten pretty hot from the work I was asking of it which tells me I am working it beyond what it was intended to do.

The reducer that you are looking at would work, the question is how long. A better choice is this one 60:1 reducer.

This gets you the output RPM you need, has enough torque output to handle what you throw at it, and can be direct coupled to a motor or belt driven at a 1:1 ratio. There is also a 30:1 reducer with similar capabilities ans also the same price.

One thing that I always look at when buying something that I want to only buy once is the shipping weight. The weight of the stronger reducers is double of the other one. This tells me that it is built of heavier components that are not as likely to fail.

You are correct about the tubing, it is 2 1/2" square tubing with 3/16" wall thickness. This stuff was scrap that I picked up. as a matter of fact, I did not have enough long pieces and had to weld pieces together to get the length I needed. If you are buying the steel, I would go with 1/4" wall thickness.

Remember my previous posts about roller size. when you go with bigger rollers, you require more torque and more reduction to keep the feed at a manageable speed.

Brian

Thanks for clearing up what the reducer see's if i was using a 2:1 pulley system. I'm thinking if i want to run a 60:1 total reduction i might as well just get the 60:1 reducer. No use in doing all the extra math <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//tongue.gi f' class='bbc_emoticon' alt=':P' /> yeah, that sounds good.

Now i have an idea of total cost of this if i buy things new. which i am always inclined to do. order of things to buy now rolling mill > paragon HT oven > forging press > Mechanical Hammer of some sort. Next year if its slow i can get the rolling mill and oven. if its a good year and i save like mad i can get the press, too <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//biggrin.gi f' class='bbc_emoticon' alt=':D' />