This is definitely the most time I have spent on a project. I found a lot of good info on ladder damascus here on the forum, but I could not decide how many layers to go for. If it helps anyone this is 102 layers. It has a cool look but I think 300 - 400 would have given me the look I was going for. I also w'd my billet from the beginning which was a first for me. Any advice is always welcome. I won't be showing but I am looking forward to seeing everyone's work this weekend at ICCE. Fort Worth is a good location for a knife show. There are also a few more pictures on my Facebook page but I didn't want to overload the forum. Thanks.

Well, I really like it! It's not what I think of when I think "Ladder", and it looks like far fewer layers than 102, but still, it's a very sweet looking pattern. When you say you W'd it from the start, I think you mean you either squared it on the bias or straight end pressed it, but you didn't tile or accordion cut it. Maybe that is why it looks so different from "traditional" ladder patterns. I really like the shape of your coffin handle. These always look best to me with that subtle curve rather than straight sides. The inlay looks great (I have to try that someday) and the hardware package is very tasteful and clean. Thumbs up all around Chad.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

|quoted:

and it looks like far fewer layers than 102, but still, it's a very sweet looking pattern.

I agree.

Possibly you can tell us a little more about how you made your billet and then the "Ladder".

Karl B. Andersen

Journeyman Smith

Yes, tell us more. But I agree, a fine job.

I like it a lot!! beautiful work!!

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

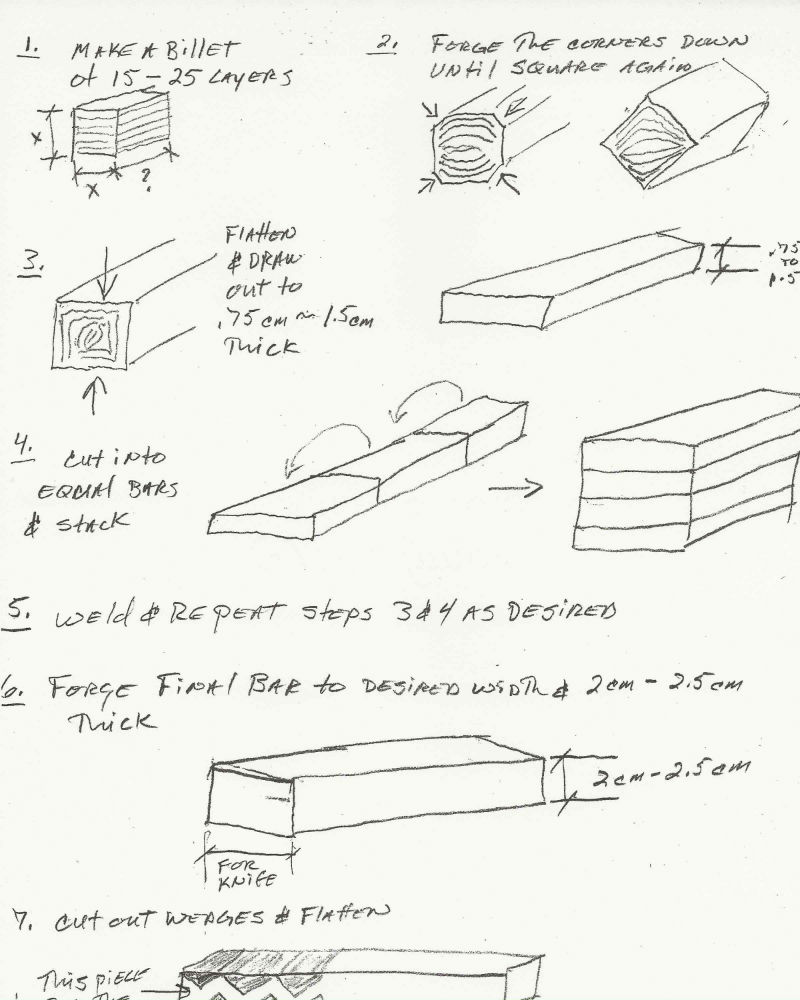

Okay. First off, it looks like I have my terminology wrong. I thought that the "w's" that you get from reorienting your billet 90 degrees was considered W'd. I am gathering that is wrong and W'd means accordion? Regardless this is what I did: I started with 17 layers of 3/16 x 1 1/2-1084 and 1/16 x 1 1/2-15N20, forged until square and turned it 90 degrees thus hammering the ends. I drew it out and cut into three pieces and re-stacked = 51 layers. I stacked edges on top of edges and not the usual flats on flats. Drew out again and cut in half, re-stacked = 102. I can understand it doesn't look like a normal 102 layers because it is more like six bars of 17 layers. You can see the weld lines if you look for them. I forged the blade to shape but left it 5/8" thick at the ricasso and tapered down to 5/16" at the tip and cutting edge. The best I can remember I cut a quarter of the thickness out every 1/2" alternating on either side. Then I just hammered it out. I followed Lin's method on a ladder damascus thread. Seems like I just had a little confusion on the W's. Thanks for the comments though.

Very nice.

Chad, I pretty much get what you did and I think your terminology is correct.

I also think your steel has some very unique character to it.

If it helps you in any way, I can tell you what I do.

I begin with 12 layers - 6 layers of 3/8" 1095 and 6 layers of 15N20.

I forge weld that billet.

Then I cut and re-stack x 4 for 48 layers.

Once welded, and reduced just a little I rotate 90 degrees to place the layers vertically and "crush" those layers into a flat bar. Those are what I call "Crushed" Ws.

Then I cut and re-stack that bar x 4 and forge weld so I have FOUR layers of "Crushed" Ws.

Again I cut x 4 and re-stack and weld for 16 layers of "Crushed" Ws.

I draw this out to about 7/16" and forge into the shape of the blade and ladder.

This is the result:

Karl B. Andersen

Journeyman Smith

Thanks Karl. I was thinking that next time I would try to get more layers. What you are saying makes sense. Have you ever tried more than 48 layers before turning 90 degrees? Maybe double it? I would love to hear how others do it and see your examples.

|quoted:

Thanks Karl. I was thinking that next time I would try to get more layers. What you are saying makes sense. Have you ever tried more than 48 layers before turning 90 degrees? Maybe double it? I would love to hear how others do it and see your examples.

Of course. But that layer count shows in in the number of rows you see running lengthwise down the blade. If you get them too fine then you lose the character you see in my blade there. Many guys do less than 48. I found 60 to be as high as I want to go.

Karl B. Andersen

Journeyman Smith

|quoted:

Thanks Karl. I was thinking that next time I would try to get more layers. What you are saying makes sense. Have you ever tried more than 48 layers before turning 90 degrees? Maybe double it? I would love to hear how others do it and see your examples.

Well, you asked for it.

I do the pattern slightly differently than Karl so I get slightly different results. A knifemaker from Romania asked me how I got this pattern, and I put together a little story board drawing for the method I use.

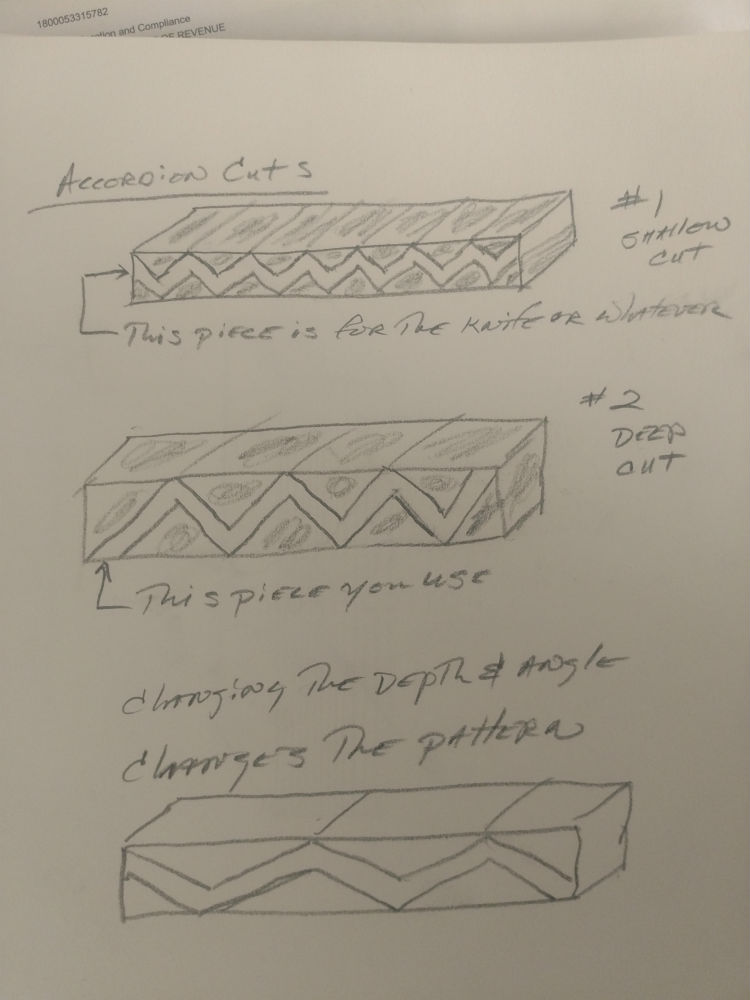

When you do an accordion cut, the pattern changes depending on the depth and width of the cutouts.

It occurred to me that maybe a thread on pattern development techniques might be a good addition to the ABS University. Folks could start adding different patterns and how they achieve them. What do you think?

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Thanks Karl. I guess you just have to play with it until you get what you want. Is accordion cut the same thing as ladder? It seems similar but Ladder seems like it just gives you a peak inside and accordion IS the inside.

|quoted:

Thanks Karl. I guess you just have to play with it until you get what you want. Is accordion cut the same thing as ladder? It seems similar but Ladder seems like it just gives you a peak inside and accordion IS the inside.

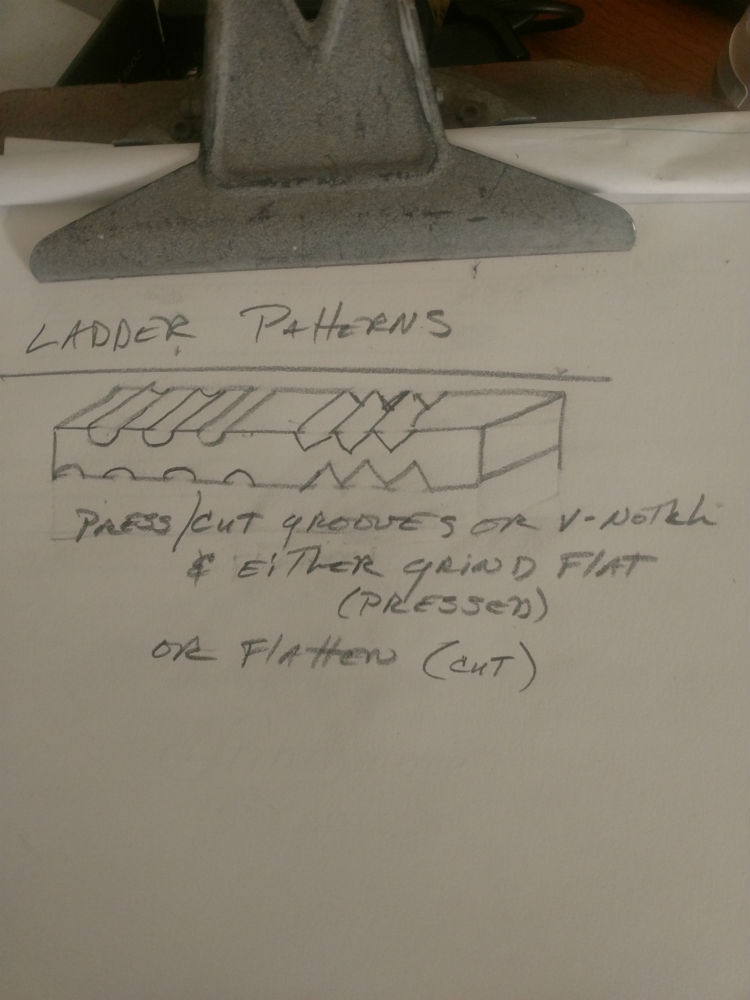

Well, I'm not Karl, but I will answer this one anyway. There are two basic methods to do the ladder: Press the grooves and grind flat or cut/grind the grooves and forge flat. The latter one is very similar to the accordion cut. Here are some diagrams.

Tim Hancock would V-cut his grooves and flatten when he wanted a wide ladder, and press/grind when he wanted a tight narrow pattern.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

A note on accordion cuts: Some people (like Gary Mulkey) like to drill a hole in the bottom of the V and then cut with a bandsaw. Some of us just cut with a bandsaw and then use the belt grinder to clean up and round out the bottom a little. You want to lay it out so the piece you use is in the 1/4" to 3/8" thick range. This leaves enough material to grind flat and true after pressing.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

|quoted:

Is accordion cut the same thing as ladder?

Quick answer - no. (I'm watching NCAA!)

Karl B. Andersen

Journeyman Smith