I don't typically do a lot of full tang knives, but when a customer from 8 or 10 years ago comes to you and asks for two more just like it with ironwood scales, who's going to refuse him?

That's what happened at the art show last November. The original was a full tang with dovetailed 416 bolsters and black linen micarta scales.

This was back in the days before I tapered the tangs and was still using 5160.

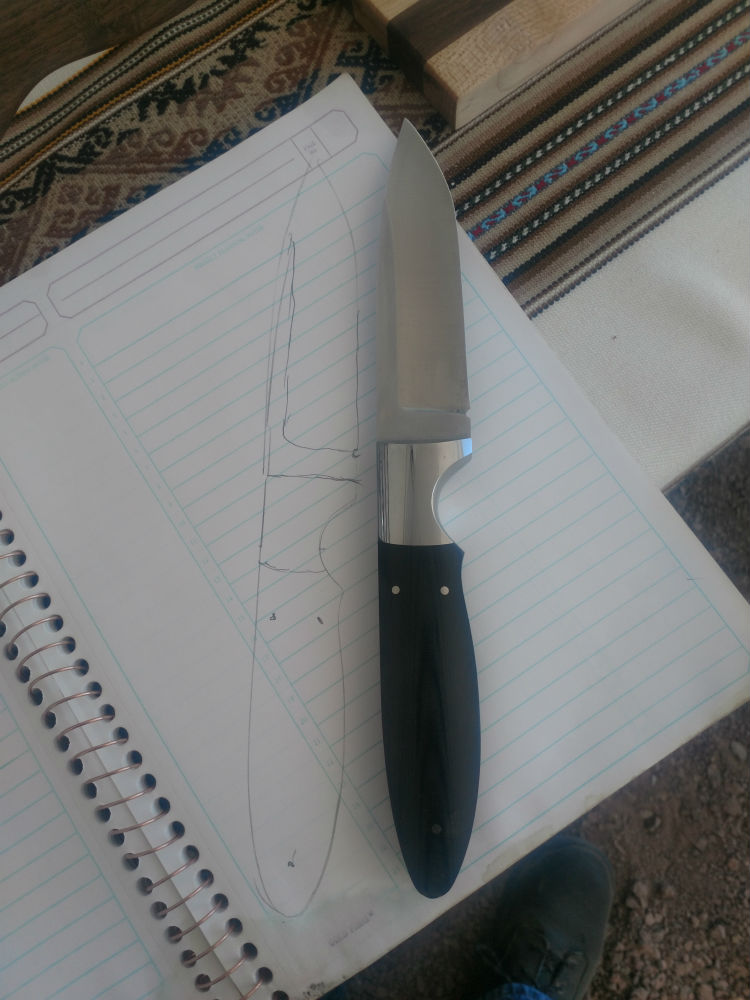

Here is the original.

So we discussed the tapered tang, the fact that I would be making them out of O-1 and he wanted some ironwood. I'll make a long story short. After the first two forgings were unacceptable and one of the second forgings cracked in the quench, and another forging cracked in the quench, (first two knives I have ever lost in the quench!) and screwing up the fit on both knives, I finally finished these two.

Let me know what you think.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Very nice work and design.

Yeah, those are real nice Joshua.

Thanks for the feedback guys. I had four commissioned knives to make since November and three of them were full tangs. The third one didn't have the dovetails and was considerably easier to make. I got out of practice on the dovetail/tapered tang combo and messed up the process sequence when drilling the pin holes for the scales. With a square backed bolster, it doesn't matter if you drill first and taper second. With a dovetail, you have to taper first or the scales separate from the bolster.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Good looking knives Joshua!!

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

Thanks again Jason. It was also a fine time to try out Nick Rossi's Two-knife challenge.

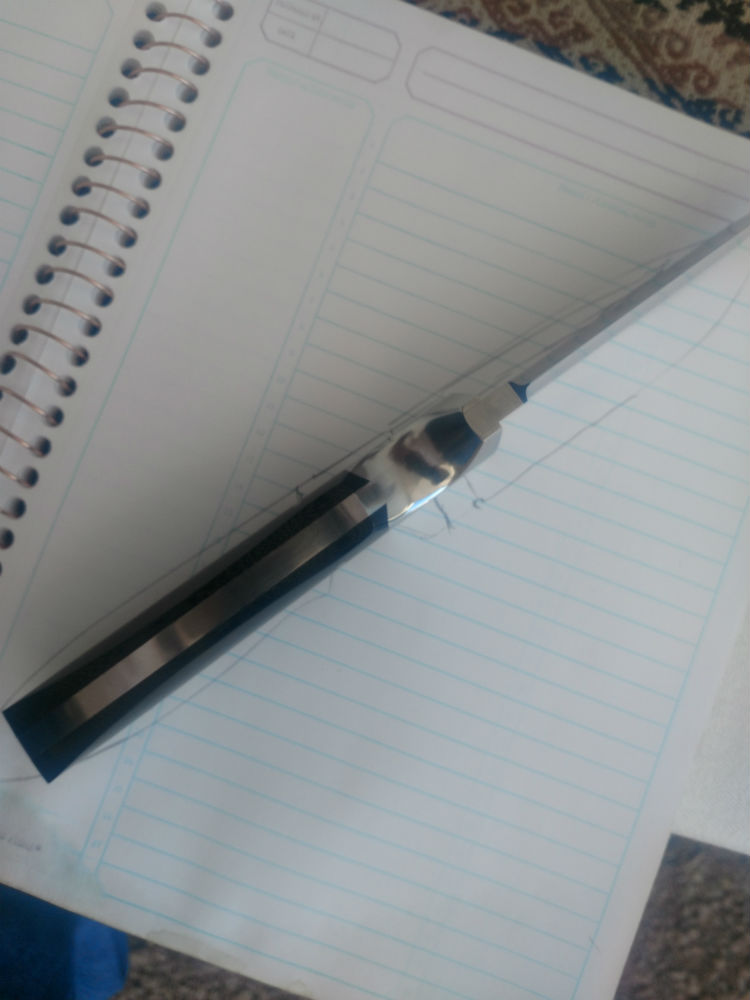

I did pretty well, even though I had to chuck the first two forgings because the were at the wrong length and width. Here are a couple of process shots.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€