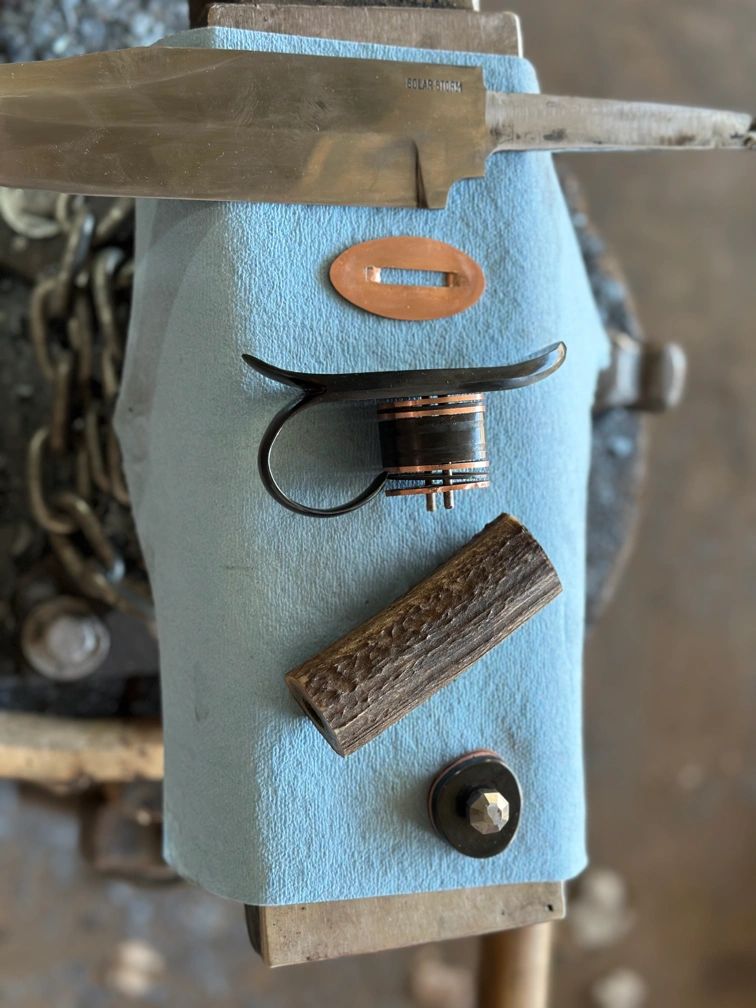

Blade is 80CRV2 Guard and spacer is a mild ( I think, picked a chunk from the scrap pile ). Blued the guard, spacer and pommel. Tried to match the first copper spacer to the antler and flair out to the rounder shapes through the other two spacers. It is a takedown, but I might have made things to tight because it is really hard to get together and hard to pull apart.

The ring guard was forged by splitting the mild steel and then drawing out a long tail. I then made the spacers and spent way more time than I should have trying to make the ring and spacer match exactly. This is the one time that I think less forging and more grinding would have served me better.

The sheath is a style I like for larger knives. The sheath comes out of the belt loop, so that when you are sitting around camp or in a truck you can take the knife out, without taking off your belt.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

I have my grandfathers old leather working tools. He was a trapper for a good part of his life and while on the trapline, he would do leather carving to pass the time.

As he got older, and his hands started failing, he passed it down to me. The main "basket weave" is just a repeated stamp.

There are other tools for making the "groves" but I really dont know what any of them are called.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke