Hi everybody,

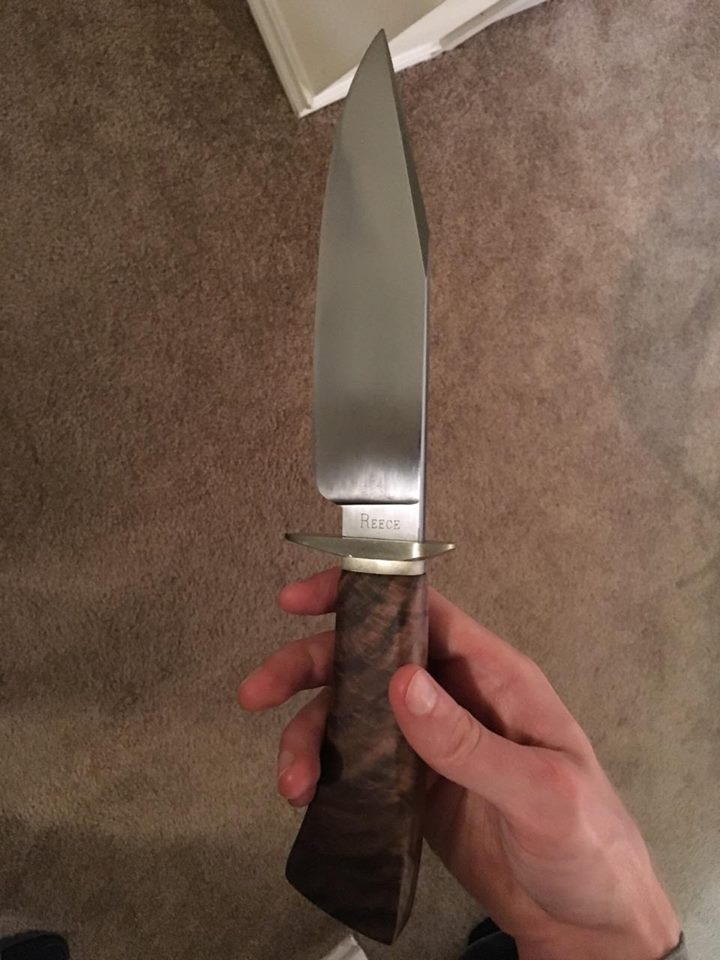

Here's my first bowie. I have a lot of thanks to give to Tim Potier, who gave excellent instruction and guidance as we worked together on it. Here's a little bit about the knife:

Blade: 6.75" 1075 steel

Fittings: Nickle silver

Handle: Walnut with tung oil

It was great fun to be able to try a project more complex than I'm used to. Thanks for looking!

Good Job Timothy. Nice proportions to that Bowie. I also like that you have not postponed putting your logo on your work. That's very important.

Very nice work! Congratulations!

Chris

Timothy

Looks good,nice work.

Anthony

Nice job on that, Timothy.

I really do like that length/size blade too.

What was the biggest challenge for you?

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Thanks for the kind words, y'all!

Joshua, I had a few challenges on this project. At Tim's shop, we were able to make it through the final grind of the blade, a bit of hand sanding, and the guard fit. It was really nice to be able to use his mill to slot the guard, so when I did the spacer on my own with just files, I felt like I was in a bit murkier waters. I was very pleased with the fit in the end though.

I would say my biggest challenge (mistake) happened when I was drilling out the handle. I had one end done and moved on to the other, drilling two holes so I could connect them with a broach. My drill press only has a travel of 2.5", so I drilled as far as I could, then moved the table up to insert the bet further into the hole. On my second go, I must have been using the incorrect speed or didn't take small enough bites out of the wood, and I ended up breaking the bit off inside the handle. I have a lot to learn as I practice with my equipment. I deliberated quite a lot on how to proceed. I ended up trying to file out as much of the bit as I could, and then cut a notch in the tang to make up the difference.

Had this knife been for a customer, I would have scrapped the handle and started over. I'm actually thankful for such mistakes early on in my knifemaking endeavors, because I feel that often a valuable way to learn is to have to solve a problem yourself. I would like to take this opportunity though, to encourage newer makers to really get to know your equipment and seek guidance from experienced craftsmen/craftswomen. I'm confident that this knife wouldn't have been half as good without the guidance from Mr. Potier.

Congratulations you did a fabulous job!

Good job Timothy! A learning experience, but worth it. I like the proportions on it. A good size.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Timothy,

Nice looking Bowie. It's easy to see TP's influence in that knife.

Bob

|quoted:

Good job Timothy! A learning experience, but worth it. I like the proportions on it. A good size.

Brion

Isn't every knife a learning experience? <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//laugh.gi f' class='bbc_emoticon' alt=':lol:' />

Timothy, those file cut fittings can be a bit nerve wracking that's for sure. Thanks for the details, I'm sure the next one will be easier......unless you decide to make it more complex! Great job.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

I appreciate the comments, everyone. It is great to be involved in such a helpful community.