I thought I would share a bit on how I make wood lined sheaths. I have been making wood lined sheaths exclusively for the last ten years. Prior to that I only made them for a few of my higher end knives. Bill Moran introduced me to the process about thirty years ago. I start out with bass wood or non acidic wood. Here are the basic steps I use and some photos for illustration

Dan Petersen, ABS-MS

Here is the list of steps:

I thought I would share a bit on how I make wood lined sheaths. I have been making wood lined sheaths exclusively for the last ten years. Prior to that I only made them for a few of my higher end knives. Bill Moran introduced me to the process about thirty years ago. I start out with bass wood or non acidic wood. Here are the basic steps:

1. Cut the wood to match the blade length with about an extra half to 3/4 inch in length.

2. Then I trace each side of the blade with a pencil onto the wood halves of the sheath

3. I then use a small carving knife to cut the outline drawn by the pencil mark up. This is a critical step. I try to cut to the depth I will eventually carve out of the wood to fit the blade. The spine perimeter is cut deeper than the the edge perimeter.

4. I then take a 60 degree gouge and cut the inside perimeter. This sets up the work for the next carver.

5. I then use a slightly curved 1 inch gouge and remove the wood from the rest.

6. I sand the rough spot and then clean the inside to remove and sanding grit material.

7. Clamp the two halves together and test fit with the blade.

8. I like to line the halves with either a find grain leather or cork. Cork works extremely well since it will compress under force and then expand to snug up against the blade. If done right the blade will hang upside down in the cork lined sheath. You can do the same with leather but it requires a more precise fitting. The leather or cork is glued with a leather contact cement (Barge). Super glue is bad since it soaks through the leather and tends to do a poor job on cork. Epoxy works but it can work deeper into the leather than I prefer. I like the cushion effect of either the cork or thin leather lining.

9. I glue everything up with epoxy and clamp.

10. I check my fit and if necessary remove any epoxy that dripped inside (requires a special tool).

11. I then grind my wood liner to shape basically just sanding the curves and rounding the edges.

12. I then sand the top of the sheath at the opening where the blade slides in. After it is sanded, I stain the wood. Frequently, I enamel this opening or use a black epoxy.

13. Now it is time to wrap the sheath in leather. I like a 4 or 5 oz leather for this. Three is a bit thin and over five gets hard to stretch over the wood liner. I find that it works best for me to cut two halves. If a belt loop is required I sew it on the correct half. Then I use the leather contact cement (Barge) and glue up the wood liner and each half of the leather. When it is slightly dry I carefully press it all in place. I use four inch wide clamps jaws to press the edges. When it is all dry I stamp and drill my thread holes and then stitch everything up.

14. I then sand the edges on my grinder first with 60 grit and then finish with 30 micron. The 30 micron or equivalent will burn the edge and slick it up.

15. Then I dye it (if needed) and wax it. A final hand buff to give it a shine.

16. Misc. The leather looks better if on pouches if a few inches are folded to the inside, clamped and glued first. For a bowie I like to add a two to three inch wide strip of leather to one or both sides to provide some contrast and extra support for a belt post. You can see the auction knife sheath for this year as an example.

Thank you for posting this Dan. It might come in handy for me soon. If there's time I'd like to enlist your directions before the Blade Show but it's coming toward us pretty fast now.

Thank you Dan. I have one on the drawing board and this refreshes my memory. Could you use velour as a liner? I have seen this on some, but I think the cork would be a better way to go.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Thanks for this. Sounds like a great WIP.... <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//biggrin.gi f' class='bbc_emoticon' alt=':D' />

I'm having trouble visualizing steps 13 & 14 and how it finishes off at the top of the sheath.

How thick are the slabs of wood when you start? How much wider than the blade are they (or is that the same as the 1/2-3/4 inches mentioned in step 1?)

I had seen on a YouTube video someone using felt as the liner, but I think the cork would probably be much easier to work with.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

I do sword scabbards similarly, I use aspen or popular for the wood, and do the carving the same way, I line them with heavy felt. I use heavy duty spay adhesive or contact cement to fix the felt in place. I add risers tot he wood by gluing strips of leather down to form my pattern, and I then wrap the scabbard in 2-3OZ vegetable tanned leather, depending n the scabbard I will stitch the seam with a number of different stitches. I have also skived down the edges of the leather for a glued overlapped seam I have also used a butted seam to good effect. I make a chape and locket from any number of materials, mild steel, bronze, brass, nickel silver, sterling silver etc.

MP

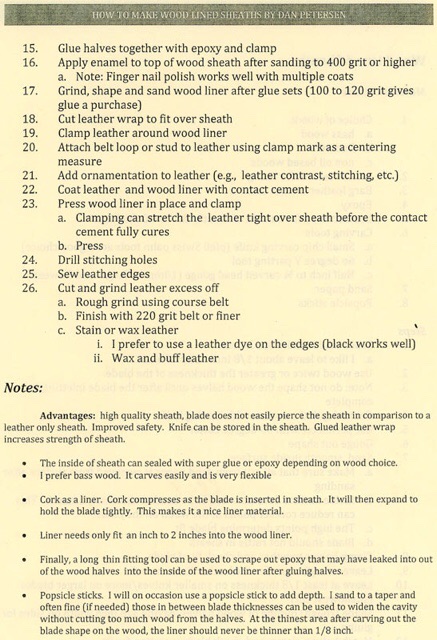

I attended Dan Petersen's presentation on making wood lined sheaths at the 2014 ABS Heartland Hammer-In in Topeka, Kansas last year. Dan provided a two page hand out which may provide more detail and answer some of the questions I see posted. This is the hand out:

-----------------------------

Example of wood lined sheath below in photo

Tools

Dan Cassidy

Journeyman Smith

Send an email to Dan

They say a picture is worth a thousand words, and so it is.

Thank you Dan, and thank you too Dan.

I bought a nice big chunk of bass wood about two years ago in hopes of trying this out. Now, I won't be reinventing the wheel, but have a great starting point.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Joshua,

If I can figure it out I will add some additional photos. For a typical hunting knife I start with two quarter inch thick pieces for a half inch thick wood liner. So for a blade that might be 3/16th in thickness that would leave a bit over 1/8 per side surround the blade. I personally do not like to go less than 1/8. However, once the leather is glued to the wood liner, the strength of the liner is greatly enhanced. Think of a long bow where rawhide was glued to the limbs of a bow to give it more strength and flex. On a typical bowie that might be 1/4 inch in thickness at the guard (or thicker), I start out with 3/8th thick wood halves.

On the auction knife for this year, the sheath liner is even with leather wrapping on the top of the sheath where the blade enters. I like this to look a little better than white bass wood. So, I can do several things. The simplest is to sand it out to 400 grit and put several coats of finger nail polish on the exposed wood of the liner. If it is a black sheath I use black finger nail polish. If the leather is brown, I use brown. On some sheaths I cut a slice of horn (buffalo) and glue it on the top of the sheath. Some sword sheaths used this decorative technique in past centuries. The only other option I have used is to cut out sheet of fiber liner material and glue it in place.

I like knowing that if a guy is wearing one of these sheaths, his knife will not puncture through and cut him. A straight leather sheath is not quite as safe.

BTW Moran sheaths are collectable. It is not just that he made them (though that is big piece of it), but that they are unique and suggest an enhanced quality.

Dan

The very first knife I ever made a wood-lined sheath for was one that Dan gave me in 1989...still have it...and I wanted that style of sheath for several knives I had but no one was interested so I thought I'd give it a try.

Here's a link to my making of a wood-lined sheath....not near as fancy as Dan's but very usable and substantial.

Thank you Dudley, for taking the time to post and share your techniques. Good job!

Dan Cassidy

Journeyman Smith

Send an email to Dan

Great job Dudley!!! Thanks for posting!

While Bill Moran was the inspiration, Dudley was the man who showed me a sheath he had made and prompted me to start only making wood lined sheathes. Thanks Dudley.

Where do you all get the cork you use for the liner? How thick does it need to be?

Dan

I would like to thank you for sharing your knowledge and experience.

Anthony