I'm not able to get Parks 50 (or other quality quenching oils) where I am currently living.

Any recommendations for W2 quenchants? I've heard (through this forum) that canola oil isn't fast enough for W2, especially when claying the blade (I'm assuming it would be too slow for an un-clayed blade as well). Hot brine is another option, but does anyone out there have another suggestion?

I've also heard of folks having success with a brine or water interrupted quench (water for three seconds and then transfer to oil for the rest of the quench). Haven't seen the results in person, but it sounds like something worth trying.

All comments are welcome! Thanks.

Try Maxim oil, 817-293-4645, they have 4 types of quench oil.

Duratherm G $60.62 (very popular, 10-12 seconds)

Duratherm (dt-48) $70.48 9.5 to 10.1 seconds, viscosity of 46-48 SUS @ 100F, flashpoint 280F <<-- #50 replacement

AAA quench $57.37 (slow)

#50 (parks) $92.01 (fast)

Parks was bought out several years ago and the new name is "number 50" but everyone still refers to it as 'parks 50' The duratherm listings they have one of them (forgot which it) is a #50 equal. They also told me there is no hazmat shipping but from your location I have no idea what shipping would be so call them up and ask <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Forgot to ask, where are you located at?

|quoted:

Forgot to ask, where are you located at?

I'm in Ecuador, so shipping is an issue, as well as import taxes, if I were even able to get it here. Since I can't get actual quenching oil, I was hoping folks had suggestions for something to use with W2 (well, besides water or brine, as I understand cracking/warping can be a major issue). I may just have to use brine and accept the losses until I move back to the States.

I've been using canola oil for 1084, but I understand that it isn't fast enough for W2.

http://www.petrofer.com/en/products/quenchants.html this company looks promising, it may not be #50 but they may have something suitable and very close.

Hought-Quench K and I believe they have shops down there.

I do find many references to canola oil being used. And W-2 stands for water hardening so water would work, brine also works as does mineral oil, canola oil, low viscosity transmission fluid (isn't parks 45 weight?)

On my w-2 datasheet it shows this.

Hardening

Heat slowly and uniformly and hold at the quenching temperature at least one-half hour per inch

of greatest thickness. Carbon grades can be quenched in water but brine-quenching is preferred

because it results in more positive response to treatment and insures uniform surface hardness.

When the section is light and maximum hardness is not desired, oil may be used as a quenching

medium. For best results, the temperature of the quenching medium should be about 70°F.

Quenching temperatures, depending upon the carbon content, are as follows:

I would think it would be worth trying to canola oil and see how that plays out, the worst case is the dreaded ping and martensite problems. Hopefully one or both of the companies I mentioned will have something you can use.

Steve, although I prefer not to use it I wouldn't count canola oil out as a quenchant fast enough to at least get the hamon area you are shooting for hard. The only thing that I have have found which will fully harden 1095 or W2 all the way to the spine without resorting to water or brine, is a very fast well formulated quench oil, yes Parks #50 is one of these. But fresh canola should be able to harden at least the edge of almost any blade, it's main drawback will be its stability over many uses which true quench oils have been designed to deal with, but you may be able to at least get your blade done and then worry about the next one later.

"One test is worth 1000 'expert' opinions" Riehle Testing Machines Co.

|quoted:

Steve, although I prefer not to use it I wouldn't count canola oil out as a quenchant fast enough to at least get the hamon area you are shooting for hard. The only thing that I have have found which will fully harden 1095 or W2 all the way to the spine without resorting to water or brine, is a very fast well formulated quench oil, yes Parks #50 is one of these. But fresh canola should be able to harden at least the edge of almost any blade, it's main drawback will be its stability over many uses which true quench oils have been designed to deal with, but you may be able to at least get your blade done and then worry about the next one later.

Thanks Kevin. I'll try canola oil first. If I do eventually try brine, at what temperature should I have it for the quench? (And when we say brine, we are talking about a saturated NaCl solution, correct?) And you're very right about Canola oil not being cheap in the long run--it just doesn't last. Any personal recommendations for a fast quench oil besides Parks #50? It seems that it is the consensus for working with W2, but what do you use?

-----

Ed--thanks for the advice. I'm going to look into South American distributors for Houghton. Ecuador is not the biggest market and folks don't do a lot of specialty work with steel here, but I just emailed the company and asked if they have someone here who carries their product. We'll see what they say. I remember seeing a map of the world at the Houghton site with their locations on it and saw that they had some facilities in Brazil and maybe Chile and Argentina--perhaps they have something here too.

Fun trying to set up a shop here--some things I can get easily and cheaply (charcoal, exotic hardwoods, leather, propane, gasoline and good guard dogs are almost free), but everything else that isn't general construction material I have to bring down in baggage. And one can't fly with corrosives or flammable liquids...thus, my issues finding a good quench medium and etchants.

Perhaps this belongs in it's own thread but here goes...

Ok I did some homework on parks #50 today myself <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' /> I called one place that had it, said $150 for a 5gallon bucket, looks to be about 65 pounds or so, figure $1 a pound to ship in the US. So approx $43 a gallon.

I then pulled the data sheet and MSDS of #50, turns out it has the following.

flashpoint 275F

Viscosity @100F 5.8 cSt

Specific gravity 0.83

this is very close to bio-oils.

Canola oil I found has specific gravity of 0.93, flashpoint 327 °C (621 °F), viscosity 9 cSt, similar but not 100%.

Also worthy of noting is diesel/kerosene/acetone has similar qualities but that's a no brainer not to use that!

One thing that really stuck out at me while looking for other fluids of a similar nature to parks number 50 is this one.

red line "like water" suspension fluid Now my assumption is parks #50 is nothing more than some type of suspension fluid, fork oil.

Looks to be around ISO VG5 to ISO VG7 which would be suitable for the lubrication of high speed spindles in machine tools, hydraulic fluid, cutting fluids, etc.

One more thing that seems to be of interest is possibly a blend of canola oil and hydraulic fluid

I quenched W-2 in canola for some time, and it hardens just fine. The only issue for me was I like to do hamons and it wasn't fast enough to give good activity. The Hamon would appear, but lower on the blade than I wanted and without any ashi, basically just a wavy line.

If you are doing a straight quench though, it should work fine, the blades I quenched in canola all were very tough and held a great edge.

Since then I have switched to water, and my hamons are much better. I do lose a percentage of blades though.

As soon as I can afford it I will try the Parks 50, from what I have seen people are getting some really nice results.

Maxim Oil in Texas has it for around $75 for 5 gal. Delivered to me in Idaho it was going to be around $150, that was about the cheapest I could find it. -Justin

I would just like to go on record that I personally do not endorse or recommend any vegetable oil or automotive product as an acceptable replacement for an actual quench oil designed, and formulated, specifically for that task. After years of hard feelings from folks who take critiques of these alternatives very personally I have found it it to be better for the peace to merely give on the canola and say it can get you by in a pinch. I have done some pretty in-depth study and experimentation with quench oils and have found that it is the complete package that seems to provide the results. I have tested oils for people trying to match certain quench oils through much lower viscosity alone, with no luck. Heat Bath Corporation is the parent company of Park Metallurgical and are who I have been doing business with for years on #50, AAA, Thermoquench and Nusal salts so I am quite familiar with that oil. In fact it was probably me that introduced it to most of the knifemakers that prize it so much, after Dan Maragni introduced me to it years ago at Ashokan. That being said Heat Bath/Park Metallurgical will no longer sell the stuff to me or you, but the best place that can buy and sell it to us I know of is Maxim oil in TX.

I particularly discourage the use of automotive products not intended to quench steel, for neither I nor the ABS would care to be associated with the health hazards involved, nothing in all of my experience would indicate that any formulated quenchant is completely interchangeable with any automotive product.

Heat Bath/Parks #50 is very good, but I now recommend Houghton International products since they are willing to sell to us and are the largest makers of such products which they offer all around the world. They have such a wide selection of oils that I am certain a couple could easily compete with HeatBath/Parks #50.

"One test is worth 1000 'expert' opinions" Riehle Testing Machines Co.

I just called them and spoke with the rep in my area, he is going to email me the quench fluids that they have available that is suitable for W2, 1095 and 5160 and I will post them here when I get them.

To expand on what Kevin just posted this article on fundamentals of quench oils is a fantastic read and explains there's more to it than just viscosity and what you are buying is reliability every time you use it.

The second link which is superb is Houghton on Quenching fantastic read on what quenching does and what product line they have available.

I also ask about obtaining their fluids in Ecuador and he is going to find that out for me as well.

----

Just got a reply.

He said on the phone they should have this stuff down there.

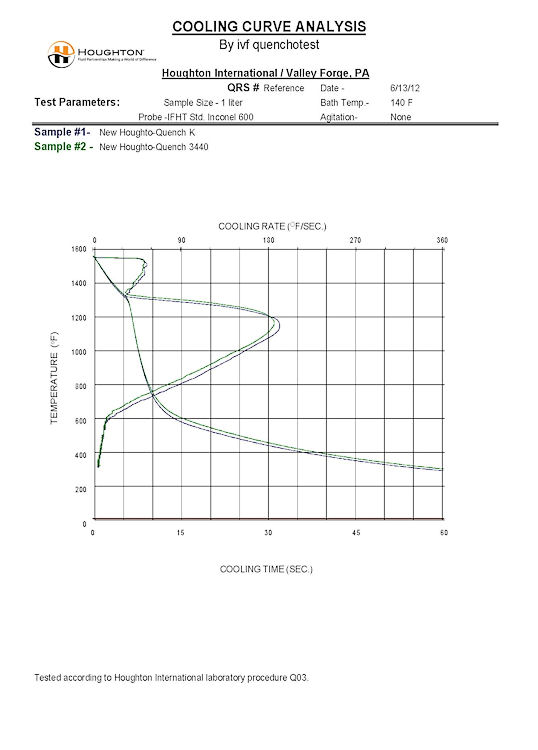

We have 2 options, Houghto quench K or 3440.

Price on the 3440 is $32.10 / Gal and the K is $34.97 /Gal.

Basics:

Quench K:

is an accelerated quenching oil suitable for use at temperatures up to 180ºF (82ºC). It is based upon specialty solvent refined base oil to minimize oxidation and ensure consistent performance under the most arduous of operating conditions.

GM-Quenchometer Speed @ 80°F (26.7°C) 7 – 9 seconds

Houghto-Quench 3440 is a fast quenching oil of low viscosity. It is based on paraffinic mineral oils and contains additives which assure bright surfaces of the quenched work and good aging stability of the oil.

GM-Quenchometer Speed @ 80°F (26.7°C) 8-10 seconds

Is it me or does Quench K look better than parks 50?

You guys are awesome--thanks for all the help. I will intensify my search for a distributor here since the Houghton rep says their products are here. Best give them a call and see if I can get a name of a company.

Thanks for all the help from everyone. Will get to work on the W2 this weekend.

As ABS Webmaster and Forum Administrator I read every post on this Forum. This has been an outstanding discussion which will benefit all of our ABS members.

I want to thank Ed Street for the time he spent researching information and providing answers to questions. I would also recommend that everyone read and follow the advice and cautions given by Master Smith Kevin Cashen whom we look to for expert guidance on heat treating topics.

Dan Cassidy

Journeyman Smith

Send an email to Dan

Great information guys , I just recieved a pail of houghton k quench this week ut haven't had a chance to try it out yet.

I googled up a list of worldwide Houghton centers/distributors, and Ecuador is serviced by the center in Brazil. I have an email in to them--we'll see how this works out.

Again, thanks for all the help and advice.

I never did learn what temperature people maintain their brine for the quench. I would like to try some hamons, and if I can't get fast quench oil it seems brine is the way to go (but to expect some losses). Well, I'll try canola oil first, as most have suggested, but also brine just to see the difference.