I'm wondering if i could get some input on sequence of working 1075. There not much info out there on it and I know some of you have experience with it any and all Information is apprieciated

Thank you

I've been treating it much like W-2 with good results. I assume your talking about Aldo's 1075, which has low manganese and is going to require a fast quench. I've been using water, but I'm sure Parks50 will give similar results with fewer cracked blades. I've found it a little trickier than W-2 for hamons (though I could just be used to the W-2) but think that it has great potential. The W-2 with a fast quench gives a sharp hamon with good activity, and tends to follow the clay. The 1075, with it's lower carbon, produces a "thicker" hamon that isn't quite as sharp. Activity wise, I've been getting at least as much as with the W-2, but it is doing some things I haven't seen the W-2 do. Namely produce a choji hamon, it is one of the more popular styles of hamons among Japanese smiths, but I haven't seen many American smiths able to duplicate it even when claying the blade in the choji style. I thing the carbon content of the steels we use plays a big part in that, and that of the steels readily available to us the 1075 is our best bet. Personally I'll continue using W-2 for much of my work but I look forward to further experimentation with the 1075.

Hopefully John Doyle sees this and responds. I know he's a fan of the 1075 and has been using a fair amount of it. In talking with him, I keep telling myself I need to give it a try.

Jeremy

Jeremy Lindley, Apprentice Smith

I found some answers thanks to some members responcse. I will try the sequence and post the results,two things the clay was to thick and I'm not getting th blade to the quenchant

Fast enough (parks50) thanks Jeremy and Justin

Scott

I love 1075. I also treat it similar to w2 as far as forging, normalizing, thermal cylcling and quenching. Tempering is a little different as I typically use lower tempering temps than I would for w2.

I find it quite predictable with relatively repeatable results. It pretty much responds accordingly to the clay placement for me. I seem to get good results as far as performance and as far as hamon activity with a short 1-2 minute soak at 1520 F. or a longer soak of 5-6 min. around 1485 F.

I admit that I have not near as much experience with w2 as I do 1075, but I think I get as much or more activity from 1075 as I do with w2.

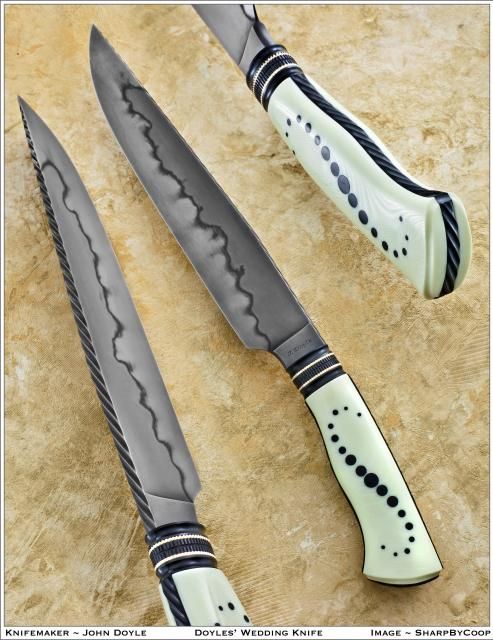

Here are some blades that I've made with 1075. I think they have show nice activity in the hamon and there is MUCH more activity than what shows as I tend to make my blades dark and that kills some of the activity I think. Even so, you can see these are quite active.

A couple quick pics showing the hamon activity of the above pair better:

And then the knife that I think is my best hamon from 1075: