I'm in the process of designing a new shop and would appreciate any resources others could point me towards so I can get ideas on layout, equipment, etc...Is there a web-site or other resource that has ideas for drawings, pictures of other smiths shops, etc? Any guidance would be greatly appreciated. Thanks. Brad K

Hi Brad. I am looking to get some feedback as well on the subject. It's a little late in my case since I have already got my new shop up and the electricity on. I have yet to finish out the ceilings and walls to completion.

I have attempted to make the most of my allotted space and set limits so I wouldn't be building forever and I have trees and septic lines to consider.

As for the shop itself, my grinding room is as far away from my office and clean room as possible. There is the forging hall between. I say "hall" because it is a 10 foot X 30 plus another 10X10 loading area in line that serves as overflow and under roof sitting. The ceilings are 10 ft. The foot print covers about 40 X 40. I can think of things that there wont be room for but I have to stop somewhere. I will be doing a video and taking some photos soon but my getting ready for the Blade Show has just about put a halt to the shop progress. I should finish it shortly after the show.

Things I have been preparing for and thinking ahead for is new technology. I have cat5e run to my office and I have electrical outlets about everywhere you look. I'll have climate control in the three cleanest rooms which are also in alignment with each other to make the actual logistics of installation easier. I have all LED lighting which are very bright and energy efficient. I'm insulating every wall and ceiling inside and out. You just never know when or how that might help.

I may try to sketch it eventually to show my thoughts on the design choices.

Hello Brad. You may find the "I Forge Iron" forum worth perusing as well. There is a subsection of the forum dedicated to building and designing a blacksmith shop. You can find it here: https://www.iforgeiron.com/forum/153-building-designing-a-shop/. I know I got a lot of good information regarding ventilation considerations and other aspects of the build I hadn't thought of initially. -Jake

Jacob T. Lutz

In terms of a single building/shop (I have two....a "forging" shop, and my "finish shop is a different building), I think it's wise to separate/partition off a grinding area. How you arrange things/machines, will likely be a year or so of shuffling things around, until you find an arrangement that works best for you.

Good electrical service is a must. Always install more plugs, both 110V and 220V then you think you will ever need..... they get used up quickly! <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

If I had it to do over again, I would have at least a 1/2 bath in my shop... it sure is inconvenient to have to run to the house, and it would provide a place to at least partially clean up before going into the house in the evening....rather than my Mrs. meeting me at the back door and pointing the the basement bathroom! <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Since I live in Montana, where the winters can be brutal, and the summers scorching, a good heat system (I have "in-floor" hot water heat in the Forging shop, set at 55F year round, and a overhead gas heater in the finish shop, that's about twice the size recommended for the square footage.), and for the summer months, a huge "swamp cooler" in the finish shop. It's not just the comfort factor, there is a bunch of stuff in the shops that if frozen/thawed, are wrecked.

Probably the most important aspect that many overlook is LIGHTING. As I get older, I find that I need more and more light. Just last fall I removed all the florescent lighting in the finish shop, and replaced it with 6000K (also called "Daylight") LED lighting. What a difference.

OH! I almost forgot the most important thing.....an area for the coffee pot! <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

|quoted:

Hi Brad. I am looking to get some feedback as well on the subject. It's a little late in my case since I have already got my new shop up and the electricity on. I have yet to finish out the ceilings and walls to completion.

I have attempted to make the most of my allotted space and set limits so I wouldn't be building forever and I have trees and septic lines to consider.

As for the shop itself, my grinding room is as far away from my office and clean room as possible. There is the forging hall between. I say "hall" because it is a 10 foot X 30 plus another 10X10 loading area in line that serves as overflow and under roof sitting. The ceilings are 10 ft. The foot print covers about 40 X 40. I can think of things that there wont be room for but I have to stop somewhere. I will be doing a video and taking some photos soon but my getting ready for the Blade Show has just about put a halt to the shop progress. I should finish it shortly after the show.

Things I have been preparing for and thinking ahead for is new technology. I have cat5e run to my office and I have electrical outlets about everywhere you look. I'll have climate control in the three cleanest rooms which are also in alignment with each other to make the actual logistics of installation easier. I have all LED lighting which are very bright and energy efficient. I'm insulating every wall and ceiling inside and out. You just never know when or how that might help.

I may try to sketch it eventually to show my thoughts on the design choices.

|quoted:

In terms of a single building/shop (I have two....a "forging" shop, and my "finish shop is a different building), I think it's wise to separate/partition off a grinding area. How you arrange things/machines, will likely be a year or so of shuffling things around, until you find an arrangement that works best for you.

Good electrical service is a must. Always install more plugs, both 110V and 220V then you think you will ever need..... they get used up quickly! <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

If I had it to do over again, I would have at least a 1/2 bath in my shop... it sure is inconvenient to have to run to the house, and it would provide a place to at least partially clean up before going into the house in the evening....rather than my Mrs. meeting me at the back door and pointing the the basement bathroom! <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Since I live in Montana, where the winters can be brutal, and the summers scorching, a good heat system (I have "in-floor" hot water heat in the Forging shop, set at 55F year round, and a overhead gas heater in the finish shop, that's about twice the size recommended for the square footage.), and for the summer months, a huge "swamp cooler" in the finish shop. It's not just the comfort factor, there is a bunch of stuff in the shops that if frozen/thawed, are wrecked.

Probably the most important aspect that many overlook is LIGHTING. As I get older, I find that I need more and more light. Just last fall I removed all the florescent lighting in the finish shop, and replaced it with 6000K (also called "Daylight") LED lighting. What a difference.

OH! I almost forgot the most important thing.....an area for the coffee pot! <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Thanks to all for your input so far...Much appreciated!

One more thing that I did in my new shop is to add a beam trolley. I can back a vehicle into the loading/unloading bay and lift a piece of equipment and drive from under it and sit the equipment down on pipes for rolling. This is requiring that I use a coil up security door rather than a garage type door. I have headroom so that's not a problem. Every possible need should be considered ahead of time. For instance, if I eventually buy an electric hoist, there needs to be an outlet adjacent to the trolley's travel. It's these type provisions along with possible technological advances in communication and security that are pretty hard for me to keep up with.

Hey Brad. I remember having this question when I was building my first shop ( an 8'x16' skidded pipe shed). But here is my layout right now. I don't have a separate forge and finishing area as I'm sure many do not, but I have tried my best. The thing I like most is the "alley" where I do most my finishing work. I can easily turn around from my finishing work bench ( i didn't draw in the vise there) and use my belt grinder /or flat grinder/ or buffer. I need to move my drill press closer as well. Saving steps is important to me. That is one reason I liked my first shop. It saves time not having to walk all over your shop. I really hope this helps.

|quoted:

Hey Brad. I remember having this question when I was building my first shop ( an 8'x16' skidded pipe shed). But here is my layout right now. I don't have a separate forge and finishing area as I'm sure many do not, but I have tried my best. The thing I like most is the "alley" where I do most my finishing work. I can easily turn around from my finishing work bench ( i didn't draw in the vise there) and use my belt grinder /or flat grinder/ or buffer. I need to move my drill press closer as well. Saving steps is important to me. That is one reason I liked my first shop. It saves time not having to walk all over your shop. I really hope this helps.

Thanks Chad...Appreciate you taking the time to give me your thoughts!!

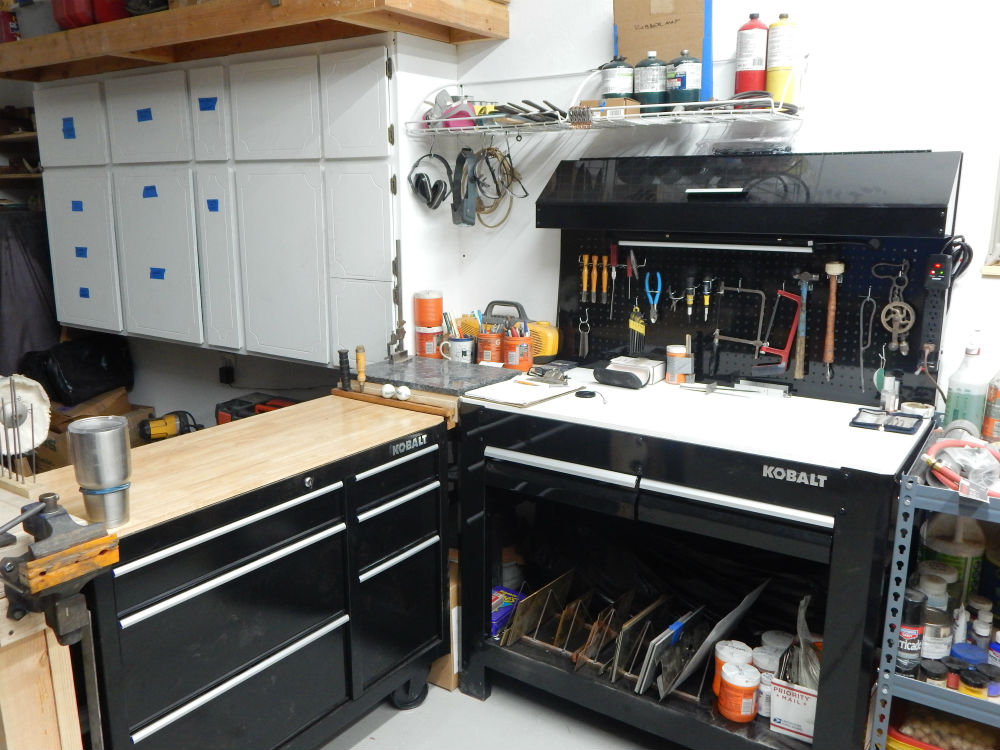

I finally got the temporary shop set up and I figured I'd post some pics of how I arranged it. First an explanation of why this is a temporary set up. We have to wait to build the dedicated shop building until a real estate deal is finalized and then we have to wait for the shop builder (steel building) to make room on their schedule, so I have to make use of the garage for the time being. I arranged it in "stations". Mind you, this shop is used by two smiths, my wife and me.

There is the forging station. Forges, anvils, press, power hammer, etc.

The handwork station. Hand tools, files, measuring, layout, etc.

The woodworking station. Table saw, lathe and 6x48 for surfacing and squaring.

My grinding station. 2x72 and 9" disc.

Liz's jewelry bench.

And a general purpose table for the welders, band saw, bench grinder and drill press.

I didn't get a photo of the small bench with the HT oven and the mini-mill and metal lathe, but it is the same size as the grinding station and faces it with about 2 feet of space between.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€