so what happens int he case of working "cross grain" that is to say, across the direction. for instance forging something from large round stock, by cutting a slice of and forging into bar if the bar the new bar was forged in a way to have the end grain on the surface of the bar. what happens then? i have done that a few times , forging knives, axes, hammers, other tools with the grain in the direction and never noticed any difference. other than one hammer with 1045 faces that the edge grain ended on the flats, when etched the flow in the steel was impressive.

MP

|quoted:

so what happens int he case of working "cross grain" that is to say, across the direction. for instance forging something from large round stock, by cutting a slice of and forging into bar if the bar the new bar was forged in a way to have the end grain on the surface of the bar. what happens then? i have done that a few times , forging knives, axes, hammers, other tools with the grain in the direction and never noticed any difference. other than one hammer with 1045 faces that the edge grain ended on the flats, when etched the flow in the steel was impressive.

MP

Matt, to give a more extreme and obvious analog to your question, I would point to “W†pattern damascus. What does happen when to forge the line in steel the other way? Well, it distorts it in that direction. “W†pattern is much more pronounced and extreme but I haven’t heard too many people say they noticed any large property differences in W pattern blades. I would expect very subtle changes in how the edge would behave microscopically, as I have observed with similar conditions.

I don’t know the source material but I believe the bottom image that Ed posted has a slight inaccuracy with the same confusion between crystalline grains and the directional properties of steel. The top image and description of the rolling mill addresses austenite grain which will be replaced on the next recrystallizing heat. In fact, if the distortion of those grains survives the rolling heat that resulting strain energy will increase the rate of recrystallization into a whole new set of grains.

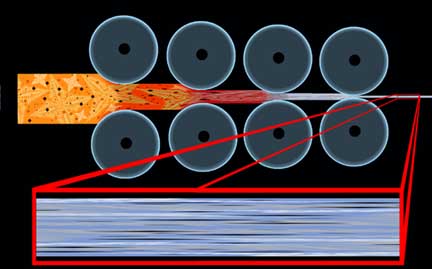

If we are talking about the more permanent directional characteristics of steel, such as alloy banding or anisotropic properties, then what the top image should look more like this one from an article I wrote quite a few years ago:

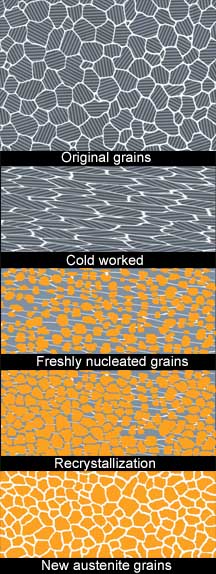

I this version it is the voids, inclusions and dendritic structures in the ingot that are being reduced and drawn out in the direction of rolling, and resulting in the directional nature of the steel. The crystalline grain effects happen within this framework but are not pictured because they are not set in a permanent state or condition. The concept of that recrystallization is illustrated in this image:

Here heavy reduction exceeding the recrystallization rate (massive hot forming or cold working) results in elongated crystalline grains. But on the next heat the stored energy from that deformation (strain) results in nucleation of an all new set of austenite grains (crystalline). So the directional characteristics resulting from the point defects being rolled out at that mill are responsible for the shaped lines in crank shafts and other forged parts, but this is not the crystalline grains which remake themselves with every heat to non-magnetic. But this is not to say that the phases made up of these crystals cannot, under certain circumstances, be steered in certain ways by the directional lines inherent in the steel. If we heavily cycle a high carbon steel at the low end of recrystallization the areas of higher alloying in those directional lines will gather the resulting carbides into the visible alloy banding we often see.

It is also very worth noting that if the crystalline grains did not totally reform, we would have no way of countering grain growth. Indeed, at forging temperatures we would simply be beating the same, ever enlarging, austenite grains. But the act of forging drives a process known as “dynamic recrystallization†in which the energy introduced by our hammers prompts fresh recrystallization at points in the steel so that we refresh the grain size while hot working and do not grow the grain. If the grain condition was permanently set at the mill, and we could not recrystallize things, forged blades would be worse than cast iron and stock removal would be the only way to go.

It does seem complicated, and I entirely understand how the directional lines of the steel are so often confused with the crystalline grain, even in print, but they are distinctly unique and understanding the differences can be important in knowing how we are affecting our medium when we work it.

"One test is worth 1000 'expert' opinions" Riehle Testing Machines Co.

I have been sitting on an article for the American Bladesmith on this very topic for a couple of years. This conversation reminded me of how deep this topic can get and how much there is to talk about, so I think I should get on that article and finally finish it, if nothing else it is a good excuse to stop procrastinating.

"One test is worth 1000 'expert' opinions" Riehle Testing Machines Co.