Joshua Good stuff!! I like that Bowie.

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

A while back I traded my Tippman Aerostitch sewing machine for some cash and 3 rounds of Don Hanson W-2. Today, I set myself to forging a dagger out of it.

I cut a 1" slice off the round bar and forged it into a 1"x3/8" bar and started the dagger.

This is the blade as-forged

This is the blade as-forged next to the template/pattern I used as a guide.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

That's gonna be a sweet looking dagger Joshua

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

I Forged out a drawknife from a bar of 1095

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Nice!! I always wanted to make a draw knife

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

|quoted:

Nice!! I always wanted to make a draw knife

This was made from a 12.5" piece of 1" by 1/4". Blade is about 8" long and 1.25" wide.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

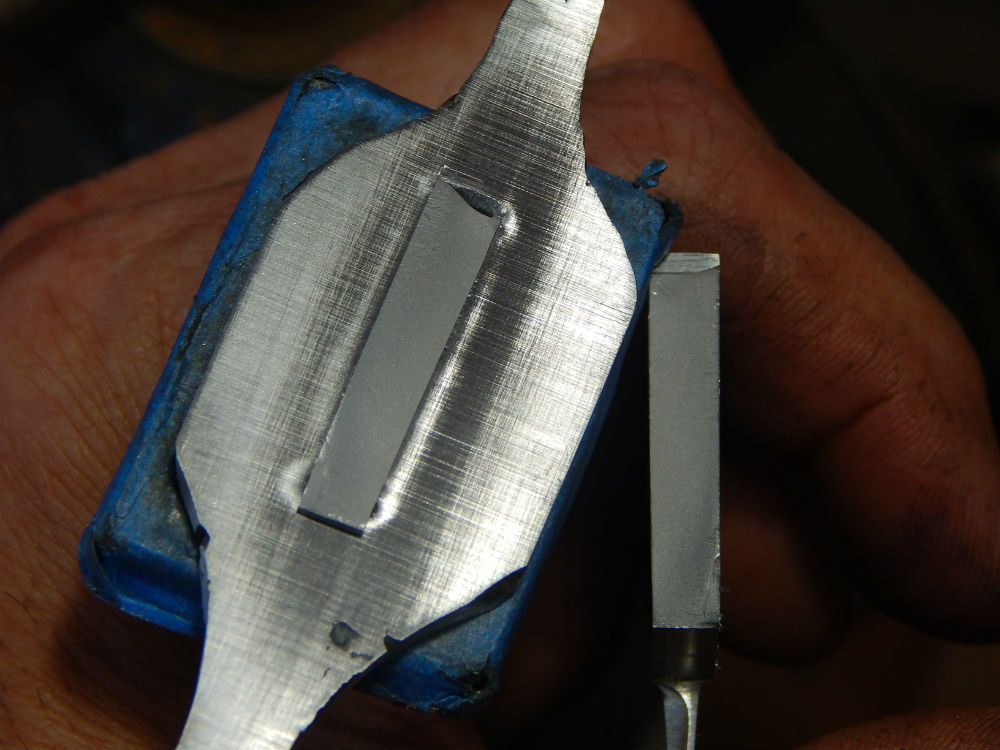

I fitted a few knives with guards. Got three out of the four I was working on.

I also forged out some 410 SS for the big Bowie. Thanks to Lin Rhea and Gary Mulkey for showing me that it's actually possible.

After getting that cleaned up and slotted, I proceeded to fit it on the knife. I guess I hit it a little too hard. I hate when that happens.

On the bright side, the grain structure looks great. At least I still know how to HT O-1.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Damn man!! That sucks!!

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

Joshua,

Your willingness to show mistakes is how we all learn. Thank you for that.

Drat - sorry Joshua.

|quoted:

Joshua,

Your willingness to show mistakes is how we all learn. Thank you for that.

My pleasure! I just wish I had learned the first time I did this...…

I try not to harden and temper the tang but the ricasso always gets in the oil. I try and draw back the tang/ricasso joint, but I guess I left this one a bit too hard. It doesn't help that I was trying to get that last 1/32" of fit and really gave it a good hit either.

JJ Simon once told me "I fail a lot, so I'm used to it" I thought that was a great attitude. I think that if you don't make mistakes and fail every once in a while, then you aren't pushing yourself. In some ways I'm happy about this. I haven't done a HT test blade with my O-1 stock in a while and I was starting to think I should check my HT anyway. Just to make sure the Paragon is set right and my method still works.

Now I get to do it all over again! Hand me that 1" drill rod captain...…. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//laugh.gi f' class='bbc_emoticon' alt=':lol:' />

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

What did I do in the shop today(last night)? I finished hand sanding an 8 inch chef knife. Going into hand sanding this knife, I decided that I was going to go above and beyond the normal scope of hand sanding and made sure that each grit was as even and complete as I could possibly make it before moving on. I didn't have to go backwards in my grit progression, and the outcome is a very clean surface that I will eventually etch to bring out the hamon. In previous sanding of a hamon blade I conceded to get most scratches out figuring that the final buffing would take care of any shallow scratches, which it did. I do believe that some of the character of the hamon was diminished by the extra buffing at the end. So I said "hand cramps be damned!" and committed to as much time as possible to get the sanding done to the absolute best of my capabilities.

This ended up taking me about 10 hours (or more i think i lost all concept of time and space) of sanding through 9 grits, and I learned plenty throughout the process. Firstly I learned that surface area matters when moving to finer grits. If your sanding block has too much surface area then you will not get the same "bite" from the paper and it will feel ineffective. I also learned that I need to take more time and care on the grinder to ensure all previous scratches are removed AND that the surface of the bevels are not wavy from heel to tip. It would be nice to have a good finish grind before going to hand sanding so that I don't have to start back down at 220/320.

An additional note about my grinding- I have been using graphite strips on my platen during finish grinding to reduce belt bump, which has been effective. It has however created a semi-convex surface on both sides of the blade as the graphite wears away. I like the fact that I don't have belt bump, but need to test if changing the graphite strip before moving to the other side of the blade is an economical strategy. I use a grinding jig, so I go through the whole belt progression on one side before going to the other side. In the specific instance of this 8" chef, I was only ginding one blade so the hollowing of the graphite wasn't that bad (despite making hand sanding a little more tedius). But if I am going to learn to grind multiple knives in a production line, the graphite may be more harm than good.

Cheers

|quoted:

I also learned that I need to take more time and care on the grinder to ensure all previous scratches are removed AND that the surface of the bevels are not wavy from heel to tip. It would be nice to have a good finish grind before going to hand sanding so that I don't have to start back down at 220/320.

Cheers

Yep. My saying that I take full credit for is, "When you're sanding out scratches - you're not sanding scratches. You're sanding everything that is NOT a scratch." A scratch is a void - an absence of material. You can't sand NOTHING. If you have a "scratch" from a previous belt grinding episode, do NOT!! try to sand it out. In essence, you have to bring EVERYTHING else that is NOT the scratch DOWN to a level equal to the bottom of the scratch for the "scratch" to go away.

That's a waste of time.

Go back to the grinder to the NEXT belt grit and grind everything down to that level and it's gone - instantly.

You just saved hours of time and aggravation and a whole bunch of sand paper.

Karl B. Andersen

Journeyman Smith

The quality of a hand sanded blade is determined by the effectiveness of the grinding.

Karl B. Andersen

Journeyman Smith

|quoted:

What did I do in the shop today(last night)?

An additional note about my grinding- I have been using graphite strips on my platen during finish grinding to reduce belt bump, which has been effective. It has however created a semi-convex surface on both sides of the blade as the graphite wears away. I like the fact that I don't have belt bump, but need to test if changing the graphite strip before moving to the other side of the blade is an economical strategy. I use a grinding jig, so I go through the whole belt progression on one side before going to the other side. In the specific instance of this 8" chef, I was only grinding one blade so the hollowing of the graphite wasn't that bad (despite making hand sanding a little more tedius). But if I am going to learn to grind multiple knives in a production line, the graphite may be more harm than good.

Cheers

Aubrey, have you ever considered getting a 9 inch disc grinder? I have been using one (variable speed, reversible) for as long as I have been making blades and I wouldn't give it up. I have tried a lot of different finish grinding/hand sanding techniques and have settled on this: I Take the blade down to 220 on the 2x72, move to 220 on the disc to flatten and straighten. Go to 320 by hand inline with the blade. Go to 320 on the disc. Go to 400 by hand inline with the blade, and so on. Back and forth from disc to hand successively with finer grits. The disc gets the blade truly flat and straight. By changing directions at roughly 90 degrees between hand and disc, I can really see that the previous grits lines have been removed.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€