This months topic is hydraulic presses. What type of designs do you use and building tips. What types of dies do you have for the press? We can also discuss different techniques for using and doing things with the press. I am looking forward to this topic as I am getting a press in the near future. So lets hear about your presses and the ways you use them.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Great Topic Brion!

To get this discussion started I am posting a video that Karl Andersen filmed about the construction, features, and use of his press. This video is on the ABS YouTube Channel. You can watch the video by clicking on the arrow in the video below.

[media] http://youtube.com/watch?v=yxsvoKSMt2Q [/media]

Dan Cassidy

Journeyman Smith

Send an email to Dan

I built my H-type press some many years ago before having seen a press for knifemaking. If you build your own; make it have as narrow a frame, as short of a frame, and of twice as thick of materials as you think. Twenty years of hard use at fast cycling will make an engineers specs look well....

And don't try to split a feather billet way off center; your squared up press will become a trapezoidal press. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//sad.gi f' class='bbc_emoticon' alt=':(' />

Mike

Mike Williams

Master Smith

I thought about building a press for two or three years but in the end bought Uncle Al's press. For $3000 shipped it is hard to beat (don't quote me on the price it's getting late). So why did I buy instead of build? Cost. At least in north Idaho, it was going to cost close to that to put the pieces together, and unless you have good fabrication skills (I don't) you aren't going to get as nice a press. That isn't counting time. It would have taken me at least a couple months to build and that's time I could be forging Damascus.

I think that if you have a well equipped shop, and good welding skills, you can probably build a press to custom fit your needs better than a commercial press. And if you don't have to pay an arm and a leg for shipping you may save some money. That said, if you are in the apprentice phase of bladesmithing, and not coming from a background in metal work, then chances are you don't have a well equipped shop and your welds (like mine) may be fine for putting a handle on a billet but not much more. For those who fit that bill, I would highly recommend buying one. These things are putting out a serious amount of pressure and you don't want one to fail. With a commercial press, the maker has likely worked out the bugs and has a solid working design.

For some reason a decent Kinyon type hammer will run you $10,000 (I won't mention names because his hammers are awesome) though the parts cost is similar to a press, but you can get a press for between $3-5,000.

Not trying to talk anyone out of building one, just something to think about.

Thanks for posting that video, Dan.

That press makes my life possible.

Even though it may not have a narrow frame, like Mike suggests, it's rated at over 70 tons, and I'm only using about 25.

I believe one of the most important aspects of a press is to have no flex, which equates to energy loss. If you can direct ALL of the energy into the work piece, the construction of the frame becomes almost more important than the mechanics of the press.

Almost.

What ever I put under those dies - I can rip in 1/2 with drawing dies.

I do all sort of things with that press.

I have a die specifically just for setting ricassos on dropped edge knives.

Ladder dies.

Integral dies.

Drawing dies.

Flat dies.

Long flatter dies.

On and on.

In the words of my good friend, Jerry Rados, "Knife making is a lifetime of buying tools......and then you die."

Karl B. Andersen

Journeyman Smith

Any other recommendations for presses that are manufactured?

I know of three other presses being made commercially (there are probably more). The Imagination Xpress, originally made by Jeff Carlisle in Great Falls Mt. is a "C" frame press. I talked to him a couple years ago and he is no longer making it, but it is being made by someone else. You would have to contact Jeff to get the info. Ron Claiborne makes a nice looking "H" frame press. His contact info is at hightemptools.com. Tommy McNabb of Carolina Custom Knives makes two presses in a reverse "H" frame configuration.

When I looked at them they all had advantages, and I have heard good things about all of them.

Ignorant questions on my part, having never used a press...

Alot of the presses I see seem pretty big, maybe 10 or 12 inches wide with 8 to 10 inches between the ram and the bottom die. I can see where splitting feather billets would need a long stroke, or some adjustability so you could make several cuts or whatever.

What are the primary uses of a press?

I'm assuming:

setting welds on stacked or can damascus

drawing out those welded billets

laddering or otherwise manipulating the billets

If that's the case, could you not use a smaller press? Maybe a 4 inch stroke on a 4-6" wide opening?

How much weight do we need? I assume the more the better, but if the alternative is a hammer, it seems like even a 10 ton press would be useful.

I have heard that ram speed is important, so you can get more strokes per heat. Is there a recommended or minimum specification for X number of strokes per minute?

I hate it that every time I turn around there's another $3000 tool I "have to" have in order to keep making progress.

Jason-

You don't have to have one, just plan on having one REALLY strong hammer arm instead <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//wink.gi f' class='bbc_emoticon' alt=';)' />. There are others way more qualified to answer some of your specific questions. I can say I've enjoyed using presses. They make very short work of some of the tasks you mentioned and save TONS of time and effort. I think the larger throw you mentioned has to do at least somewhat with the "what if". Like, what if you really get into pattern welding and start doing the large "loaves" that end up in several billets? For some stuff, you need some of that extra room to accomplish the task. So, if you only use half the distance built into the press most of the time, it's really nice having the extra room those few times you need it. Other than a bit more money in the ram to ensure the longer throw, I'm guessing the cost difference is negligible were a guy building his own press for a slightly longer/taller frame.

That being said, I really want one, but simply don't have the room. I have acquired a 20 ton air/hydraulic jack and plan on building one of the mini presses to sit on my metal table next to the forge. It's got a lot of limitations compared to a full size press, but it's a fraction of the cost and takes up far less room, while opening the door to some stuff that isn't very easy to do by hand.

Jeremy

Jeremy Lindley, Apprentice Smith

I think it has more to do with longer stroke cylinders being more common and easier to source than any real need for a longer stroke. In my shop we have a 26 ton H frame press that we have used to make thousands of architectural parts from house made dies, even with this kind of work we rarely use more than a 1/3-1/2 the stroke.

MP

One thing that Uncle Al's press has going for it is being able to adjust the length of stroke. Say from eight inches down to four. A great thing if you are doing damascus. Less time between up and down means more squeezing before the billet cools. I just got mine about two weeks ago and have already found it is much faster than my little giant when drawing billets. Still a lot to learn but it definitely makes my life easier. Still there are things the little giant does better, like drawing out tangs and forging blades. Glad to have both. No you do not have to have a press, but if you are trying to make a living, any tool that will speed up your process is a help.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

I have one of Uncle Al's presses. I believe it is a 24 ton. It has a 5 inch diameter cylinder with an 8 inch stroke. The pump is a two stage, and I believe it is 16 GPM at 3,000psi.

24 tons is plenty of pressure for most work. The only time I feel I could use a stronger press is when using pattern dies. However, this is not a major problem and you just have to take smaller bites on the work piece. Maybe this is a good thing and prevents you from ruining a billet by having so much power that you work the steel too cold, or too much. Thinner material is tougher to move with a press than thick material. A large billet is easily moved in a press. With thinner material, the dies suck the heat out of the material quickly and it takes more power to move the colder material. It's probably better not to have a monster press that can crush a billet when it is too cold for forging and blow welds.

A two stage pump is what you need for ram speed. The first stage of the pump is larger volume and less pressure. The first stage moves the ram quickly to contact the work. When the ram closes on the work piece, the pump kicks to the second stage which is slower, but is higher pressure.

The eight inch stoke length is adequate for most work. It's enough room for large billets and/or elaborate die set-ups.

I made a splitting die to do feather patterns, but it there is only enough room to do a billet large enough to make a hunter blade. I doubt that I could split a billet for a large bowie. I heard about one knifemaker who has one of Al's presses, that made a splitting set-up that attached outside the H frame of the press. I think this would work, but you would want to be VERY careful about how you designed and used it to keep from bending the press parts.

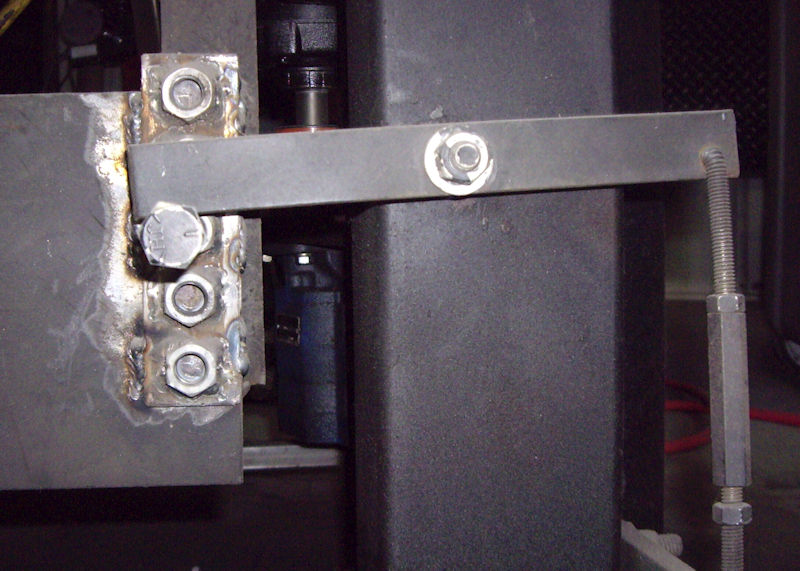

I modified my press by adding a way to easily adjust the stroke length. I welded five nuts to a strip of steel, on one inch centers. Then, tack welded the strip to the press's ram. I can move a bolt between the nuts, to control how far the ram returns towards the top of its stroke. This keeps the ram from going all of the way to the top of the stroke and shortens the time required for it to contact the work piece.

I have a 50# LG hammer and use it for setting welds and doing most of the drawing out of the billets. I use the press mostly with pattern dies and for final dimensioning of bar stock. But, the press can do anything needed. If a knifemaker can only afford either a press or a power hammer; I suggest buying a press. A press can do things that are difficult to do in a hammer.

One thing I have learned. On really cold days I will heat of block of steel and put it between the dies of my press. They seem to really pull the heat out of a billet otherwise. You can see the heat leaveing the billet. I've had billets pop open, a few times, until the dies heat up.

Recently my cylinder started to leak around the shaft. After pricing a new cylinder, I checked on a re-build kit. $27.00 and about an hours work and the cylinder was good as new. Something to keep in mind if you get a leak.

Dale

Dale Huckabee

Journeyman Smith

dalehuckabeeknives.weebly.com

To address some of Jason's questions

The size of the press is determined by what you are going to put in it. I built my own press and it is a C frame type but if I did it again I would probably go with a H style. I have it set to max out at about 20 tons, but rarely max it out.

The press itself can be easily carried by 2 people as I just have it setting on stand with wheels on it. While this "bench top" model may seem like it is not strong enough, it is every bit the press that others are using. Remember, everything below your bottom anvil is just a stand.

On the stroke and cycle time, when I am drawing out a billet, my cylinder only moves 1" max --probably closer to 1/2". I only have my dies open up enough to allow me to move the billet and then I press again so the movement of the cylinder is minimal.

Brian

I too use an Uncle Al press and have come to depend on it. In addition to the flat dies which I will always use more than an other, I have gone to using some beveling dies a lot. These can save a lot of time when bladesmithing. They won't draw the edge of the blade down very thin but will do most of the heavy work and are nice for establishing the plunge.

Some other dies that are very handy in addition to patterning dies (like ladder dies) are squaring dies which can lend themselves to doing some nice touches to various "W" patterns. I have used them for 4-way up to 9-way "W"'s. They are also great for forging a can.

Gary