This months topic will be on cutting competition knives. Types of steel commonly used, designs, and heat treating, plus whatever else we can think of.

First, these knives are usually 10 inches in blade length, measured from the front of the guard. The handle is a maximum of 5 inches for an overall length of 15 inches. Blades can be a maximum of 2 inches wide. This is the standard size. These knives are expected to handle a variety of cutting chores, such as 2x4's, rope, ping pong balls, oranges, apples, straws,etc. These can be the same as using the knife around the yard or farm. Cutting tree limbs, clearing brush,whatever. The trick is to make a knife that does all these things fairly well. This is where design and heat treating come into play,especially heat treating. You have to be familiar with your chosen steel and know the heat treating regimen well. Another factor is edge geometry, too thick and your knife will not cut well, too thin and it might chip or roll. This is why testing and research in your shop are very important. So we can discuss all these aspects and your thoughts on these tools.

Personally I prefer 5160 or 9260. I have worked with both steels extensively and know the heat treat very well. I am also working with another steel that is still in testing stages as far as heat treating and edge geometry. So far it is doing well. I prefer a spearpoint or bowie design with a clip, close to ten inches in blade length. Handle material will usually be horse stall mat.

So lets see your thoughts and questions and see what comes about. I will add more as we go along.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

I would like to comment first on the knife size restrictions. To me, this is one of the wisest of the standards in cutting competitions. Why? The competition is a game of factors. When a standard size is mandated for all, then that becomes a known factor. That's one factor that's out of the way and cannot be debated at any point. The size restrictions provide a one dimensional foot print for all the competitor's knives to fit within.

Of course, other factors and variables are able to be successfully, or unsuccessfully, addressed in the knife's design. But, the size restriction affects all other factors, which requires the maker to squeeze all the necessary design features into the same standardized package. In my opinion, this is what pushes the makers to make better knives for the competition and forces them to think about the very small details of design that can make a big difference in the knife's performance.

All of that serves to foster detail oriented thinking. Brion can back me up here. At any of the cutting competitions, all of the competitors will be wanting to see the other's knives. That could lead to discussions of why the various knives are design the way they are. The newer cutters often need suggestions to help with their designs. The more experienced cutters should be willing to help and explain why when suggesting changes.

Size restrictions, in my opinion, are good for us as makers.

I'm with you Lin,

I think that size restrictions inspire creativity. You have to do the best you can with what you have, relying on edge performance, geometry and skill to win.

The most important aspect is that it creates a culture of using knives. So many custom knives never get used in anger, and seeing makers using their cutlery like nature and god intended is good for the ABS and good for custom knives.

I am liking Sir Aldo's 1084 for competition knives, but you may not want to listen to me because I was only runner up at the New England Hammer In... I'm coming for you this year David Sylvester!

-Nick

I also agree that the size restrictions are a good thing, and they "level the playing field"....forcing detail oriented thinking, and innovation.

Personally, my favorite steel for a competition knife is SUJ-2 (Japanese 52100). I've won several competitions over the years using it. I believe there are some major differences/considerations between competition blades and "User" blades, and each requires keeping the "end use" factors in mind.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

Brion;

A great topic; I think.

Am leaving for the NSMW intro class in the morning so I am going to ramble a little and try to make more sense when I return.

As one of the original instigaters of cutting events for the ABS and having done several of them all over the country in the last 10 or 12 years; a few things seem to be a constant.

Steels; almost any knife quality high carbon will do fine if you know how to work it properly. Properly heat treated and tested. You must know your steel.

Size limitations; does sort of level the playing field. But; an event set up properly gives the shorter blade some cuts that actually give it an advantage over the blades that may be longer and heavier. There is more to a competition knife or; any knife for that matter; than just chopping.

Overall geometry and edge geometry play a much larger role in how a knife cuts than plus or minus an inch in length.

In 1992 I watched Bill Moran snip a one inch rope with a six inch utility knife. It was all I could do to cut the rope with a great big one at the time.Skill and geometry or geometry and practice.

Handle shape. One of the most overlooked factors. It must want to stay in the hand through any and all kinds of cut. Be very usable and comfortable through any kind of cut. If you can't work the knife hard for five minutes and the handle still feels great in the hand?

When I see a guy show up to cut with a knife that has a blade or handle shape that is just going to be impossible to do well with; one thing is certain. He has not been really, seriously, testing his knives.

It's like having foot long handles on your post hole diggers; no matter what the story is; he hasn't dug too many post holes.

Holler back at you guys in two weeks.

M

Mike Williams

Master Smith

I agree with most of what Mike just said. And the part I dont exactly understand, I think I know what he's saying. I'm refering to the "plus or minus an inch in blade length". I believe he's saying, a well balanced and designed knife with a 9 inch blade will perform better than a poorly designed knife with an eleven inch blade. I certainly agree.

This is my point about size standards. By setting this limit, it removes the chance that there are two well designed knives in the pack, one with a ten inch blade and one with an eleven/twelve inch blade, again both knives well designed, I believe the longer blade might give that person the advantage, even if it's percieved advantage. The advantage due to the longer blade is arguable since a quick lighter blade will have the advantage for some cuts.

But here is where I think there might be a real advantage for one using blades over 10 inches if they are allowed. If it's known that the competition is open class with no limits on blade size, logically the event organizers will/can choose at least some of the events that would be more suited to longer blades, thus leaving the guys with 9 and 10 inch blades at a disadvantage. Just sayin it could happen. With standardized size limits, no one, even the event organizers, would ask a cutter to perform a cut that's not possible to do with a 10 inch blade.

I'm just throwing that out there. It's no big deal either way. But I think there are some compelling reasons to set the standards mentioned. One other thing. If there are set size standards, the differences in technique can duely be attributed to the cutter with no credit to excess blade length.

Technique......that's another story.

OK, guys, you have some great advice so far.

Now, for those not all that familiar with effective competition knives, could you post up some pictures of knives you have competed with successfully and give a little dissertation on what points you do, or don't, like about them? (I'm trying to get some tips for the knife I'm supposed to bring to Arkansaw!) <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//biggrin.gi f' class='bbc_emoticon' alt=':D' />

Karl B. Andersen

Journeyman Smith

Brion Tomberlin has posted a very interesting Topic of the Month for November and in the first day of posting there have already been many helpful comments and useful advice posted.

We have many new members that have recently joined the ABS so it may be helpful to them to also discuss in more detail heat treating techniques, blade design, and handle shapes for cutting competition knives. Please also post photos of your knives.

They say that a picture is worth a thousand words...and a video even more...

This is a photo of Russell Roosevelt cutting through multiple water bottles at the ABS Mid America Hammer-In in Troy, Ohio.

_________________________________________________________

[center]

Cutting Demonstrations with Mastersmiths Cook, Williams, and Fisk

[media] http://www.youtube.c...34vuX1lA&sns=em [/media]

Master Smiths JR Cook, Mike Williams, and Jerry Fisk demonstrate the cutting potential of their forged blades on water bottles, rope, cans, and an apple.

[/center][/center]

Dan Cassidy

Journeyman Smith

Send an email to Dan

You're going to get a range of opinions about blade design. I have come to appreciate the more traditional shapes such as we might think of as a Bowie blade shape. While it's true the "cleaver" shape does well when the competition is set up where most of the events are chopping of some sort, when a competition that's well thought out with a variety of cuts (notice I didn't say chops)is held, a bowie blade does well. It's generally designed to perform all the events, more or less leaving the user to provide the necessary technique to be successful. Even among Bowie blades, some employ better("better" could be a matter of opinion) geometry, profile, and weight distribution to make it perform better.

I think of the knife and the user each providing 50% of the total sum. The user has to provide the technique and the knife has to have the qualities to perform. One or the other will likely be stronger. The user has to tailor the knife to his techniques or tailor his techniques to the knife. Each competitor will be doing some of both.

The first place to start is to think of some cuts and what technique should be employed.

The 2 X4 chop is straight forward. Hard direct blows needing stamina and stratigy from the user and strength and edge holding ability from the knife as well as a properly shaped handle. I think of the Vikings.

The rope cut is somewhat different. That takes concentration, speed and timing, from the user and a very sharp edge and flowing geometry. I think of the jungle knives and the Japanese sword techniques.

The cola can slice (can is empty and cut diagonal) The user has to think speed and motion all at the same time. This is a slice more than a chop. I think of the Japanese sword techniques.

With any cut, you can draw from your study of the different techniques and when the knife is lacking, you, as the user, have to make the adjustment to make it work. In other words, a Bowie knife is not a Japanese sword, so how can you employ the Japanese technique in the cut? You may have to lower your body, shoulder , and arm to get the blade to approach the object in a slicing motion instead of a chop.

That's going to take practice and some thought not only before any competition, but before you make the knife.

There was some talk at the Heartland Symposium about ABS competition knives needing to be differentially H/T'ed in the future. Has anyone heard more about this?

Gary

There is a lot of talent in the American Bladesmith Society and I thought that it would useful to this discussion to post some photos of our member's knives that have been used to win competitions around the country including World Cutting Competition Championships.

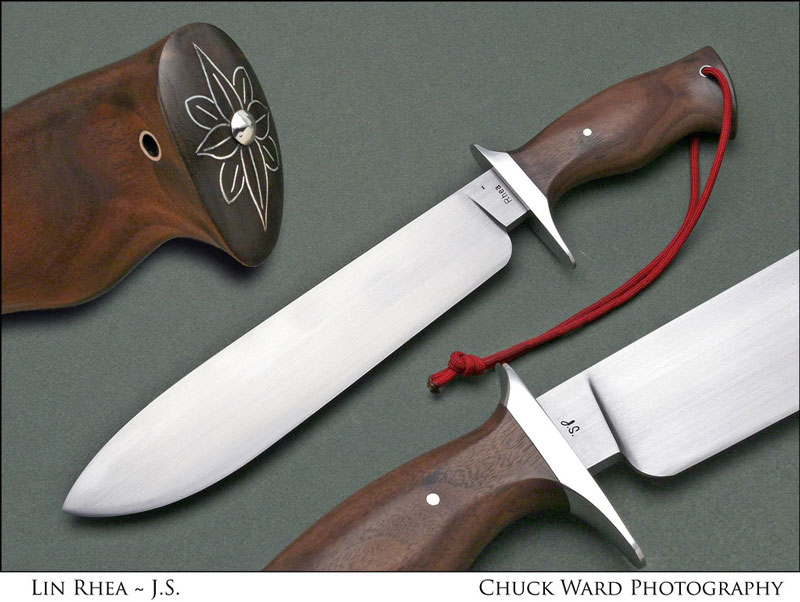

Master Smith Lin Rhea - 2006 World Championship (5160 blade steel and walnut handle)

______________________________________________________________

Master Smith Lin Rhea - Current Cutting Competition Knife

_______________________________________________________________________________________

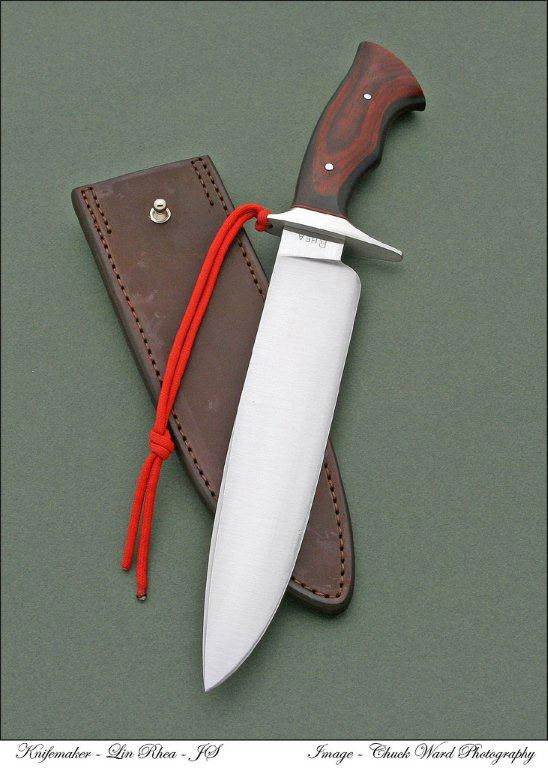

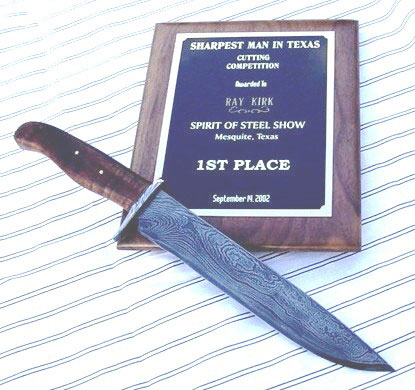

Master Smith Adam DesRosiers - 2009 ABS Smoky Mountain Hammer-In Champion (1095 blade steel and curly American Walnut handle)

______________________________________________________________

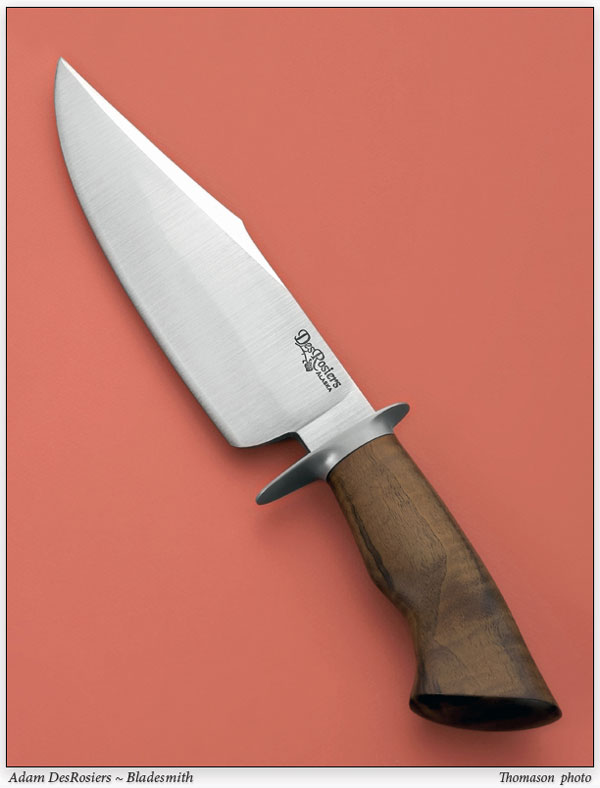

Master Smith Ray Kirk - 1st Place Champion 2002 Spirit of Steel Show

____________________________________________________________

Master Smith John Fitch - 1st Place Champion at numerous ABS Hammer-Ins

_____________________________________________________________________________________

Dan Cassidy

Journeyman Smith

Send an email to Dan

All of my knives are differentially heat treated to some extent. Are they performance test knives with dead soft spines? No. I dont want one to bend when under heavy stress, I want it to flex. It's still differentially heat treated. The cutting edge is the hardest gradually softening on the way up and back, but not dead soft till it reaches the tang/ricasso juntion.

I've seen a few bend and take set during the 2X4 chop in competitions. I believe there is a misconception that the best knife blades are drawn down dead soft on the spine. This belief stems from the way we are taught to heat treat a performance test blade. Drawing the spine is recommended for the test blades. Sure. Other than that, I dont draw the spine dead soft and I dont draw the soft area down very low on the blade. A dead soft blade feels dead in the hand and it dont perform as well. Especially when it will bend and take a 10 degree set if you slap it across a 2x4 on it's side.

I've seen one blade break in competition due to being too hard at the tang ricasso junction. Either way, something was done wrong in the heat treat.

I heat treat mine the same way Lin does. I do not want a dead soft spine. I want flexibilty in my knives, not bend and take a set. One exception is my big cutter which is 1095 with a hamon. However the spine is almost 3/8" thick and there are zones of hardness even in a blade with a hamon. I will post some pictures tomorrow showing some different designs.

One thing, all cutting knives must have at least one pin in the handle and a lanyard or thong for your wrist. As Lin mentioned I also prefer a bowie blade shape. The cleavers seen now in some competitions do very well on a number of things, but what happens if you have to stab a ping pong ball or water balloon? I like some type of point. I will talk some more tomorrow.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

What prompted my question was the shattered blade in Topeka. This knife failed during the 2x4 chop and appeared to break on both sides of the 2x4 leaving basically three pieces. The grain in the steel was a little large but I believe that the majority of the problem with it was hardness.

Since I promote an event at which we compete in front of the public, safety is always a huge concern for me. I have debated whether it would be advantageous to require some sort of test of the competing blades prior to the competition. I would welcome everyone's opinions on this as many of you have much more experience with competitions than I.

Thanks in advance.

Gary

Gary,

If the grain was large, that certainly contributed to the break. If it was not differentially hardened or not softened back in "zones", as Brion mentioned, there will be potential for breakage and possible subsequent injury. That is why the ABS is holding classes to teach this stuff. In the class, we are taught precautions throughout the blade forging/heat treat process that would greatly reduce the likelihood of such a catastrophic failure.

The maker of the knife you mentioned might have forged it too cold. He may have not drawn it back soon enough after the quench, leaving it sit fully hardened, creating micro fissures in the blade not visible but manifesting itself in the sharp blows of the 2x4 chop. In the case of the knife in question, it evidently was not thermocycled properly.

The maker should test at home, not hoping upon hope that it will "do just fine" in a competition. Our biggest asset as ABS makers is our ability to discuss the intricasies of heat treat and construction. I'm borderline OCD about my blades anyway. That slows me down, but it serves to make sure I dont let one get by that is not safe to use.

I think each competitor/maker should be able to describe in detail the heat treat if asked by the competition judges. Of course, that's not fool proof. I'm not sure what the answer to your question would be, but I dont think we should be afraid to have competitions out of fear of liablity. Every maker that walks up to the line to compete is accepting liability. He can forgo the event. The competition is literally a test of the knives and the cutters. I may be stating the obvious but, there will be some failures.