I may get my hand slapped for this by the veteran smiths, but I accept the risk... lol.(I say this because I don't see this technique discussed, anywhere.<img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//unsure.gi f' class='bbc_emoticon' alt=':unsure:' />)

On knives whith geometry that suits this technique(mostly full flat from edge to spine and no damascus), I will hammer the majority of the bevels from one side, only flipping to straighten. At this point, it resembles a chisel grind. Afterwards, I turn the blade over, line up the opposite side to the plunge and give the ricasso a solid flat blow, essentially twisting the tang and ricasso(or blade, depending on your point of view) to be inline and centered with eachother. I find it works well but you have to make sure to normalize at least twice... you may get warp during the quench if you don't. I have not ran into any issues, yet. Like I said, it doesn't fit all blade types but it sure is a handy technique for the bladesmithing toolbox.

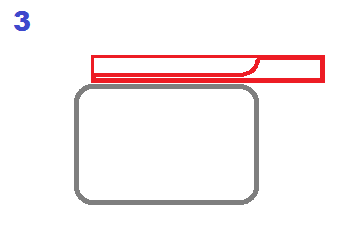

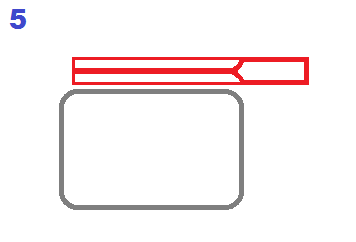

Here are a series of poorly drawn pics to better illustrate...

Hammer from one side, setting a deep onesided plunge.

Turn over, line up the plunge and strike the ricasso squarely.

That's a good idea. I'm gonna have to try it next forging session. I'll let you know how it goes.

No hand slapping here Rick, but I would be curious about the incidence of warping. That is versus a blade that has been forged evenly on both sides.

Does it make it cut better for a left or right handed person? <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//biggrin.gi f' class='bbc_emoticon' alt=':D' /> Sorry I could not resist.

Rick if it works for you, great. Everyone has different ways of doing things.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

You will get warping if you don't normalize well. As with any forging operation you need to be at proper temperatures, too. Because I don't have to worry about angling the blade to match bevels, I found that once I knock in the corner, I can begin hammering further back from the edge and move the metal much faster. I have used this method with 5160, 1070, 1084, 1095 and O1 without significant warping issues. Obviously, I do get blade warp from time to time but nothing that leads me to believe it is a result of this forging technique.

Thanks.

Rick

Rick

That is an interesting method and it just goes to show there is always more than one way to do something.

However, the most important point of this post (in my opinion) is the diagrams that you used to give a visual representation of your method. Your diagrams made it very clear what you were talking about with text. Just goes to show that a picture is worth a thousand words!

Thanks for taking time to make them.

Brian

Rich

I also want to thank you for taking the time to prepare and post the diagrams which clearly show your method.

Dan Cassidy

Journeyman Smith

Send an email to Dan

I believe Don Fogg done some of his forging from one side. He kept his edge centered by holding his steel at a angle to the anvil. This is second hand info from a guy who done some forging with Don in green coal at a hammer in. Never tried it myself, but its a interesting idea.

Bill Wiggins