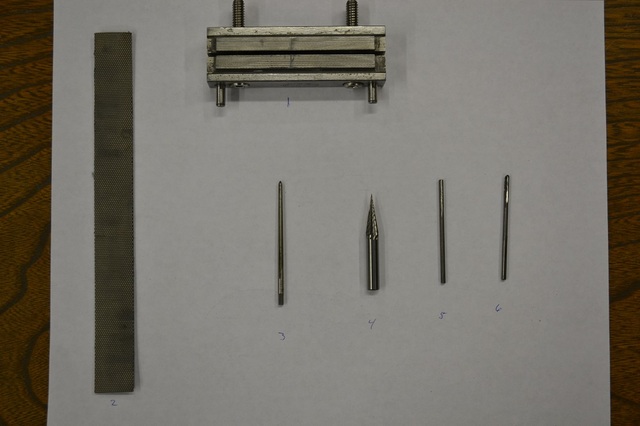

Some of the small tools I will use;

#1 is a file guide mine has carbide faces. Make sure you have a good one without a bunch of slack.

#2 is a diamond sanding strip in 400 and 800 grit. 3M makes some similar, I will have to search them out as Rio Grand no longer carries these. Phil Dwyer found some diamond strips, at: http://www.fdjtool.c...fo/ST7673N.aspx

#3 is a 4/0 tapered reamer HSS from MSC. I use these in the handle material just prior to putting the knife together. Click: MSC item#02400976

#4 is a carbide taper from Texas Knife Makers Supply. This is for tapering the bolster holes before peening the pins so they will hide.

#5 is a carbide 3/32 reamer. MSC item #79890166. Click: MSC link

#6 is a carbide .0970 reamers for reaming the blade pivot before putting the knife together. Click: MSC item #79889226

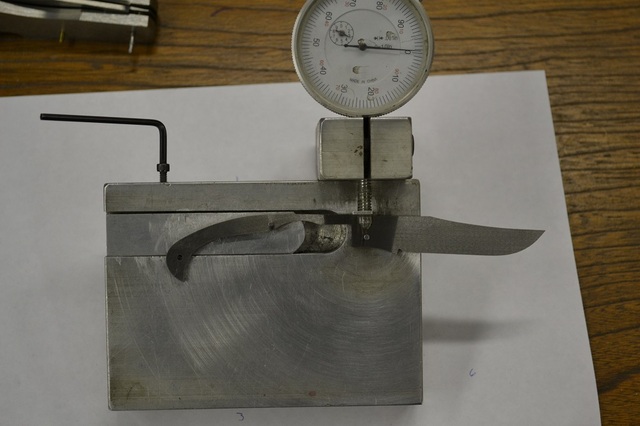

This is a rise and fall indicator. I made mine but they are available from USA Knife maker and Riverside machine. You can get by with a piece of wood with holes drilled for the pins. I use this to get close before heat treat.

A pair of 4" vice-grips modified to hole pin stock without slipping. Open them up and use a Dremel cut off disc to cut a small slot in one jaw.

Tooling plate with clamps I will use to mill the integral liners/bolsters.

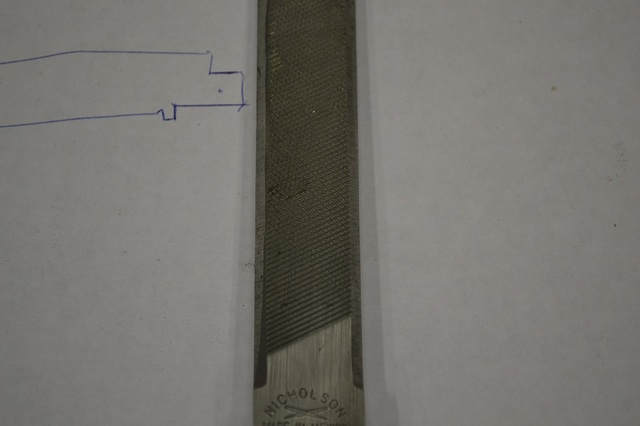

A file with the edges tapered to allow filing the notch on the blade. This notch is less than 90 degrees and a standard file will not work.

3/32 drill bit, .003 shim stock or a feeler gage blade, 3/32 pin stock. Blade and spring steel, liner material and bolster material. 410 liners and 416 bolsters for those wanting to spot weld or solder. You can use brass and nickel silver if you want. I use solid 416 for the handles. Something to use as handle material. I use a lot of jigged bone from Culpepper and really like their RJB goldenroot bone.

Something to keep the spring contact area from being eat up when we open and close it while working on the spring height.

Craig, thank you for the list of things needed and where they can be purchased. Landon

PDF file of the pattern we are using, the handle on this one is 3 5/8.

I got the reamers and a ruple dial ordered today should receive them in the middle of the week. Patterns hopefully tomorrow and I should be ready to get started next weekend. Landon

Woohoo, got the metal patterns in the mail today. Thanks Craig! I've just been an occasional carbon steel smithing hack so far, so this is going to be quite an adventure.

Going on line to order the various bits and stuff.

I've found precision ground 3/16" CPM154 at Jantz. They also have the 410 steel for the liners and 416 for the bolster. What thicknesses would you recommend?

Geesh, this is going to add up.

[list]

The reamers are an investment, as long as I don't break the buggers. The steel will be able to make several knives, so that's good, assuming I can accomplish the making. I've got the file guide. Will use a board or bar of some sort for pinning preheat-treat fit-up. I'll slog through the cutting, grinding and filing as best I can, pretty much by hand.

Found some diamond strips, http://www.fdjtool.c...fo/ST7673N.aspx . Will those do?

Don't think I can manage welding bolster/liners with my Lincoln buzzbox. Will solder I guess. Can you solder stainless? Will I need foil for heat treating? Can I oil quench?

Yes that is what I use. It works well for places that are hard to get to and is a little faster than sand paper. Try it in 400 and 800 grit.

1/8 416 will work for the bolsters. You can use carbon steel for the blade and spring if you want. If you are using stainless you will need some foil. I have never oil quenched CPM-154. If you are using CPM-154 you can send it to me for heat treat and surface grinding if needed. 3/16 is thicker than what I would use for a folder like this I like 3/32.

I use the tapered pin reamer for fragile handle material like ivory or pearl. If you were not going to use bolsters I would us it in micarta or G10. If you are not using bolsters you can skip the tapered carbide reamer from TKS. You can solder stainless, tin both pieces first. Here is a video of Tony Bose soldering bolsters.

[media] http://www.youtube.com/watch?v=SQEQkz4TjVU [/media]

Yes Craig that sounds good. I would like to join in. I would vote for the saddle horn pattern.

Thanks Craig.

If I'm ever going to get a bit familiar with stainless now's a good time. Having experts willing to share their wisdom is an invaluable opportunity.

Not sure why I specked out 3/16. That would definitely be pretty clunky. Will get 3/32. What thickness do you suggest for the liners?

Will see about hunting up some foil and quench plates too. Any recommendations?

Is your heat treat procedure along these lines as describe at Evenheat? Do you cryo too?

CPM154 Heat Treat Procedure w/ Plate Quench

All three of these, heat treat the same. After a full speed ramp up to temperature, they soak 45 minutes to an hour in the Evenheat Oven at 1950°F. Then they get placed - still in the foil - spine down - then flat - on a 1" aluminum plate. The second aluminum plate is placed on top and pressure is applied. We used to use weights for the pressure, but now we use clamps. You are looking for good firm contact. If you are thinking hydraulics you are thinking WAY too much pressure. After 2 minutes (or less) they will be hand cool, and ready to remove from the foil for cryogenics. They don\'t have to go straight into cryo, but aim for something less than an hour from plate quenching. We use liquid nitrogen for cryo but dry ice in acetone will also do. The household freezer is no use at all. They probably only need a couple hours in cryo, but we leave them overnight.

The next morning, they will be in the range of RHC63+. After warming to room temperature, they get tempered. We temper twice at 500°F for two hours each time - to get about RHC61. You can experiment for other hardness\'s but 61 is a very good target for these steels.

Same wrap - same temperature (1950F) - same soak time - same plate quench - same cryo as 154CM above. This steel gets double tempered at 400°F for about RHC60.

.040 - .050 on liners works good, I get it from K&G for center liners on multi blades. For foil I think USA knife makers supply has small amounts get the high temp rated stuff. Foil. Check where you are ordering other supplies and tools to save on shipping.

I use a similar recipe I start at 1400 for 10 minutes then up to 1950 for 45 minutes. Plate quench in the foil and blades only into liquid nitrogen for 5 minutes to over night. After quenching you have a short period of time that you can straighten by hand if needed.

Blades temper at 450 for 60 RC and the springs at 1170 for 46RC 2 hours 2 times. I start tempering the blades and springs at the same temperature (450) for the first 2 hours while the evenheat oven cools. After an hour and a half I set the evenheat at 1170 and turn it back on to heat up and even out again. I take everything out and quench in water and put the blades back in the small oven at 450 and the springs in the evenheat oven at 1170 for 2 more hours. If you are not using cryo try tempering the blades at 400.

Craig, If doing integral bolsters what thickness material would recommend. Landon

I use 1/4 inch from SB Specialty Metal. SB Specialty Metal They also have 3/16 ground 416 that may help those without access to a surface grinder.

I have some 3/8" 416 I will just mill it down. Thanks Landon

|quoted:

Yes Craig that sounds good. I would like to join in. I would vote for the saddle horn pattern.

Mr. Fuller, the pattern is on the way should be there around Thursday.

I'm late but really want to do a slip joint I'd like to join in if its not over, I have a kmg,disc grinder,Mill and surface grinder attachement and small wheel attachment with wheels down to 1/4"

Thanks Anthony