Hello again Gentlemen,

I'm in the market for my first grinder and I'd like to hear the opinions of the people who use the heck out of them.

Beaumont KMG-10 or the Wilmont TAG-101?

The difference is about $1000, and a horizontal option. I know it's a vague question, but I want to hear all the pros and cons you have.

Thanks for your time.

Personally, I think that you'd be pleased with any of the "top end" machines. Of the two you mentioned, I would personally go with the KMG. Its not necessarily the fact that one is "better" then the other, but there are such minor differences between the "top end" machines, that other factors need to be considered.... such as customer service.

The price difference is because of the lack of a motor/controller on the Wilmont..... from what I can tell.

I can only tell you what my experiences with each has been, and in all honesty, aside from a couple of modification I did to the KMG I own, it's performed flawlessly for more then a decade. I've used a couple of different versions of the Wilmont machines in other makers' shops, and all of them had "issues" that to me would be a deal breaker if I were considering purchasing one.

In the end, it's all going to come down to what YOU want, and more importantly what your budget dictates. Here's my advice.....if you buy a grinder based solely on a lower price, there's a reason for the lower price....think about what that/those reasons are. If you spend the extra money it get a "top end" machine, it's going to do everything you want it to do, AND if you ever decide to sell it, it's going to bring the same, or nearly the same money as you paid for it. On the other side of the coin, if you purchase a "lesser known" grinder, it MIGHT....or MIGHT NOT do all you hope, but it's also a sure bet that it's resale value will not even be close to what you paid for it.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

I have used both. The Wilmont TAG I tried came with a VFD. The Little Buddy unit did not, but if you wanted it with one you could order that version. If my choices was either of those 2 machines and space was a concern I would get the TAG. It will take all the same accessories as the KMG plus I like their tool rest better. Bill Wiggins has one in his shop with a KMG rotary platen on it.

Works like a charm. Very stable and vibration free.

The package with the motor and drive is Package C.

I have 2 Wilmont TAG and 1 Little Buddy. For sure I would go with the TAG if it were my primary grinder from Wilmont. Chris is great to work with and a fine knife maker so he knows what a grinder should be. I also have 2 KMG. They are fine grinders but lack the fine tuning adjustment for tracking. The spring tensioning also is limited but I have had mine in service for nearly 18 years and work them hard all day. The tooling arms for the KMG and Wilmont are interchangeable so that makes it easy to order the Wilmont TAG and the Rotary Platen from KMG. The Rotary Platen is a great accessory and worth the money. Another consideration is the Wuertz. I also have 2 of them. Travis Wuertz is also a Knifemaker and knows grinding. He has quite a few accessories. The reciever for the Weurtz is smaller than the Wilmont and the KMG so the tooling arm is not interchange able. However you could buy the Rotary Platen from KMG and a tooling arm from Weurtz and it will work.

The KMG is tough. I put 5 hp motors on both and you can really bear down on rough grinding.

The small wheel (1" and smaller) tooling from Wuertz are a better design than what you get from KMG or Wilmont but they are easily adaptable.

If I were to rely on 1 grinder it would be either the Wilmont or the Wuertz. The fine tuning for tracking, spring tensioning as well as the variable speed motors are both top notch. My guys run these grinders 5 days a week 8 hours a day and both are well suited to the job. They can both be easily changed from vertical to horizontal grinding. This is important for some grinding operations.

Other than your brain, your grinder is the most important piece of equipment in the shop. Don't skimp on your primary grinder.

Daniel Winkler

I have three baders and a KMG, the baders are good grinders but all three have run into tracking problems over the years. the KMG is a great grinder,I just dislike the belt drive, I can feel it slip and when I need to adjust it. I prefer the small wheels for the bader,I actually sold off the KMG ones, I have the rotory platten, I thought is was going to me extremely useful , but in practice dont really like it.

I have used a number of other grinders, in other shops and at school when teaching, the only one that stands out is the Wuertz TW90 I would love one of those...

MP

the only one that stands out is the Wuertz TW90 I would love one of those

I've wanted so badly to like the TW90, but had some bad experiences with them in other peoples' shops. The deal breaker for me is the 1 1/4" aluminum tooling arms. I just don't think they are stout enough to hold up. In one instance I saw a guy accidentally drop the tooling arm on concrete, and it tweaked the tooling arm to the point where it couldn't be used. In another case the "hold down" bolt/handle had chewed up the aluminum so badly that it was difficult to get the tooling arm in/out. Of course that's repairable with a file or minor grinding, but that shouldn't happen. Maybe it's the stubborn side of me, but if I'm going to pay that kind of money for a grinder, I won't tolerate annoyances like that. If the TW90 was built with a

1 1/2" steel tooling arm, I'd consider it one of the best, but as I said, the 1 1/4" aluminum tooling arm is a deal breaker for me.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

I really like the light weight if the AL. Arms, I am going to replace the steel ones on my KMG with AL over the summer, I really like the lighter weight. My only complaint with the TW90 was the guard on the tracking wheel ... I found it a pain to change belts with it in place ... Easily corrected with a zip wheel.

I have to agree with Ed. I used a Wuertz for a couple of weeks. The aluminium gets chewed up too easy. The KMG has it's downsides but for an all day every day grinder it does hang in there; mine is almost fourteen years old.

A rolling platen is a must have in the shop.

Mike Williams

Master Smith

I am going to replace the steel ones on my KMG with AL over the summer

A few years ago I tried that....using an aluminum tooling arm on the KMG..... I was back to steel within 4 months. The end of the bolt that maintains the tension chews up the aluminum just as I mentioned, and getting the tooling arm in and out of the socket became a pain. I also found that with an aluminum tooling arm, certain attachments displayed a lot more vibration then with a steel tooling arm, especially if it involves a serrated wheel. For me it just turned out to be a waste of money.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

I agree with Mike Williams and Ed Caffrey. I have had a KMG grinder for about ten years without any issues.

Dan Cassidy

Journeyman Smith

Send an email to Dan

|quoted:

A few years ago I tried that....using an aluminum tooling arm on the KMG..... I was back to steel within 4 months. The end of the bolt that maintains the tension chews up the aluminum just as I mentioned, and getting the tooling arm in and out of the socket became a pain. I also found that with an aluminum tooling arm, certain attachments displayed a lot more vibration then with a steel tooling arm, especially if it involves a serrated wheel. For me it just turned out to be a waste of money.

I have one AL arm and haven't noticed any issue.. but it is an arm I don't use often. I was also considering stainless tubing I made up on arm with it to hold my Bader wheels on the KMG. It is light stiff and harder then the Al just more difficult to fabricate due to the need of adding material for the threads by welding in threaded tubes etc that was why I was planing on going over to AL arms.. might need to rethink that.

MP

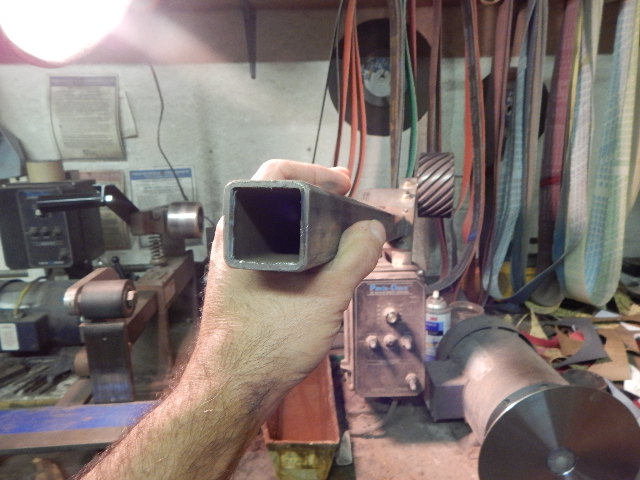

I tried square tubing too... it was awful. I think it has to do with the weight and how "solid" the tooling arm is.... the tubing caused terrible vibration, mostly when I would bear down. On my machine it caused what I'll term as a " loud hollow echo" type of sound, that made it uncomfortable to run the grinder without earplugs in. I was just using mild steel tubing, so maybe it would be different with SS tubing?

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net

I have a bunch left over from a railing job so its worth trying ...

Travis Wuertz made me a surface grinding attachment for my KMG http://www.traviswuertz.com/?product=surface-grinding-attachment-for-kmg#comment-834 and he provided a 1-1/2" x 1/8" wall square tube for the tool bar. I have been using this setup for a couple 2-3 years with no issues. Agreed, I do not put as many hours of time on this as do the full time makers in this conversation, but you guys who would like a lighter bar might consider changing to this size tubing. I do not know what type of steel the tube is, but I'm pretty sure that Travis will tell you exactly what it is.

And FWIW, I have a KMG and it has performed exceptionally well. I like the versatility of the design. It is very easy to make custom work rests for and other attachments. Aside from some very minor mods, I use mine almost exactly as it came from the factory. You can make a small wheel attachment that takes the Bader style small wheel. The KMG small wheel set up is limited for wheels smaller than 1 inch. It is also easily modified to eliminate the belt drive and go direct drive (I haven't done this yet, but I have seen it done).

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

I have a KMG and a Wimont. This is not a fair comparison by me because they are set up differently . My KMG has a single speed with step pulleys, it does good work but is loud and vibrates some. The Wilmont with the direct drive is smooth as silk and very quite. The lack of vibration has cut down my grind time and finish time and has also reduced my belt use. The infinitely adjustable rest (comest in 2 sizes i have both)is also a very useful tool. I do a lot of facets on my handles and it helps dial them in with ease. In my opinion the Wilmont is far and a way a better machine but you have to decide if it's worth the money. For me it is. What ever you decide get variable speed and the largest motor you can afford.

Steve Watkins

www.ironmanknives.com