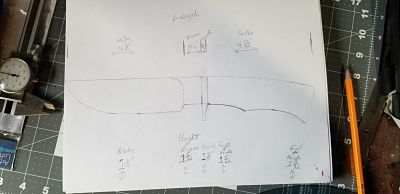

Ok so I have only made a few knives. After reading through this forum, I see a lot of the master on here recommend designing the knife first on paper and work off of that. And that makes sense to me so I gave it a try. My first 3 knives I just went to my forge and forge 1 out but I didn't like they way they came out and I know I can do better. So here is a pic of what I put on paper. I was wondering what everybody thought. Any changes I should make

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

Looks good to me. Rarely did my knife come out exactly the same when I started. 10 years later about 85% of my forged knives are within 92% the same blade length, handle shape, and finish. Remember these are custom ordered knives that I make one at a time. As you make more you will get the better. The more you make the better you will get. Pick a small blade, and make 20 of them. Next pick a larger on, and make 20 of them. When you have made about 50 or so knives you will have a feel for what you like...

This is one of my favorites after 10 years of making them...

|quoted:

Ok so I have only made a few knives. After reading through this forum, I see a lot of the master on here recommend designing the knife first on paper and work off of that. And that makes sense to me so I gave it a try. My first 3 knives I just went to my forge and forge 1 out but I didn't like they way they came out and I know I can do better. So here is a pic of what I put on paper. I was wondering what everybody thought. Any changes I should make?

Will this be primarily a skinning knife?

"One test is worth 1000 'expert' opinions" Riehle Testing Machines Co.

|quoted:

Looks good to me. Rarely did my knife come out exactly the same when I started. 10 years later about 85% of my forged knives are within 92% the same blade length, handle shape, and finish. Remember these are custom ordered knives that I make one at a time. As you make more you will get the better. The more you make the better you will get. Pick a small blade, and make 20 of them. Next pick a larger on, and make 20 of them. When you have made about 50 or so knives you will have a feel for what you like...

Thank you Mr. Brackett for your advice. I really appreciate.

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

Hello Jason. The drawing looks good, there are a couple things I might change. One, make the guard thicker. Use thicker material for it. With the size of the knife the thin guard looks out of place. Maybe 3/8" thick. Also shorten the ricasso just a bit, unless you are planning to have it be a place where you can place a finger to choke up on the blade. Other than that, good design.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

|quoted:

Will this be primarily a skinning knife?

Mr. Cashen I was thinking more like a general purpose knife. But I do see why you ask this. I didn't really notice it when I designed it but I do now, that the belly is big and the tip is blunt. I wanted to make more of a general purpose knife. Do you suggest that I make the tip more pointy or should I make it a drop point or something else. I am new to this and appreciate any advice I can get. Thanks in advance.

Jason

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

|quoted:

Hello Jason. The drawing looks good, there are a couple things I might change. One, make the guard thicker. Use thicker material for it. With the size of the knife the thin guard looks out of place. Maybe 3/8" thick. Also shorten the ricasso just a bit, unless you are planning to have it be a place where you can place a finger to choke up on the blade. Other than that, good design.

Brion

Thanks Mr. Tomberlin. I appreciate the advice. I see what you mean about the size of the guard and the ricasso. Something did look off to me but I just couldn't put my finger on it.

Thanks

Jason

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

One thing about the drawing. I would draw the tang, at least, in dotted lines. This will allow you to know where the tang needs to be right from the forging stage. Draw your pin (or pins) first and then center the tang on the pins and then you're covered. I use a thin Plexiglas to scribe over the drawing and cut that out and transfer to aluminum. Then the aluminum pattern is good from now on.

|quoted:

One thing about the drawing. I would draw the tang, at least, in dotted lines. This will allow you to know where the tang needs to be right from the forging stage. Draw your pin (or pins) first and then center the tang on the pins and then you're covered. I use a thin Plexiglas to scribe over the drawing and cut that out and transfer to aluminum. Then the aluminum pattern is good from now on.

Thank you for the advice Mr. Rhea. That makes perfect sense to me for drawing the tang out. I don't have any plexiglass or aluminum. I do have some thin sheet metal. I think I will transfer it to that. I plan on starting this project today.

Thanks

Jason

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.