I have tried my hand at CuMai, the first one was a small skinning knife, so it wasnt that hard. The 2nd attempt is a 6" knife. While I am pleased with the result, I came dangerously close to the copper hitting the tip on one side. I tried to forge it evenly in the press, alternating sides, but still seemed to manage to push the tip over.

Any tips and tricks to keeping the center in the center?

My First one - small so it was easy

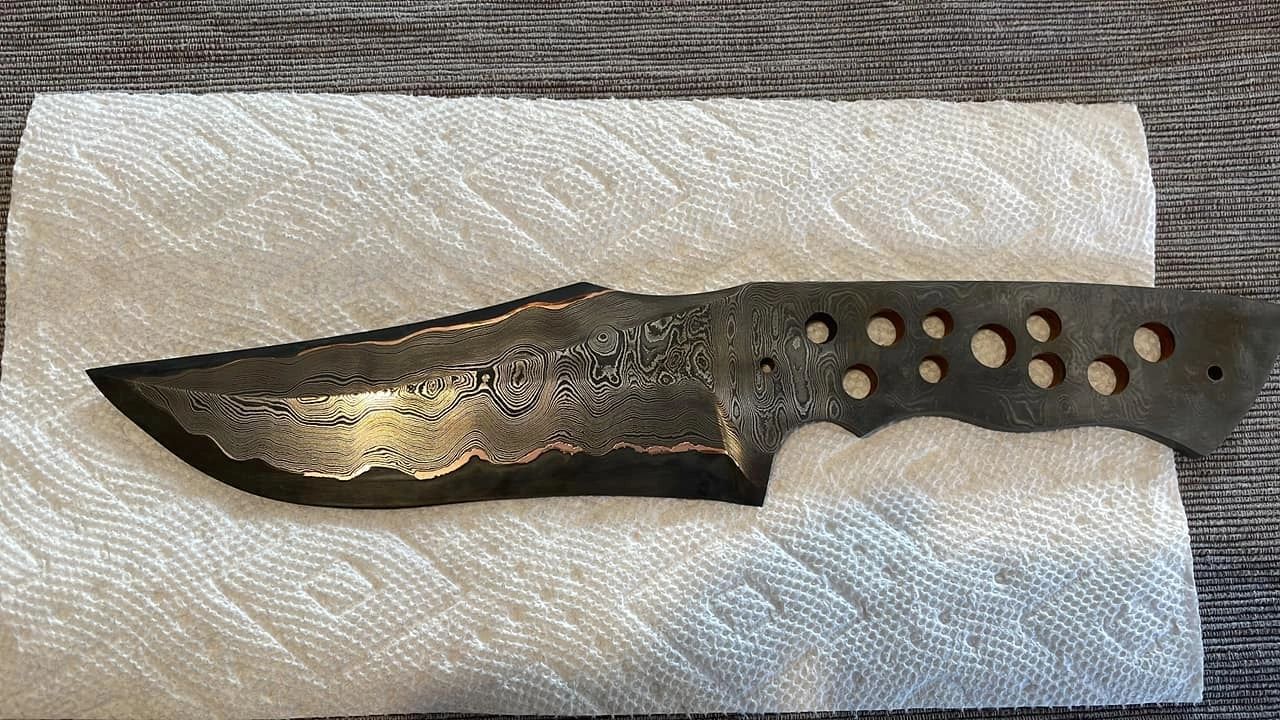

My 2nd one - a bit larger with a more complex set of bevels.

(the side that almost ruined it)

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

Not familiar with that technique. I’m pretty new (and new to the ABS community as well). Just wanted to say that looks really nice! Great work!

I’m going to have to look into this technique—I’m intrigued. Always looking for something new to challenge myself.

Just curious if you’ve ever tested one, how well it holds up?

-Rob

The top knife was used to skin a moose, and since the customer has bought 2 more knives from me, I am assuming he is happy with it.

The core is still a solid piece of 1084, so I cant see why it wont hold up well. I do find having a kiln for heat treat really helps as the copper can melt very easily if you let the temperature get away from you.

Thanks for the compliment. I am just starting my 3rd year of bladesmithing (part time) and trying to make each build a new challenge.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

Yeah I’m about 8 months into it, but I’ve made a few dozen blades and starting on a pretty ambitious Damascus billet right now. All of mine I’ve just given away so far because I want to know how they hold up over time before I consider selling them.

Going to research this process and I’ll try to make one and beat the crap out of it to see how it holds up! My guess is it’d be fine for a slicer, but not so much for a chopper. Probably a few months out though because I want to make the best piece I can before the show in Ohio in March, just so I can bring and get some critiques from more experienced smiths.

here is the finished blade.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

Roller Mill. My last major peice.