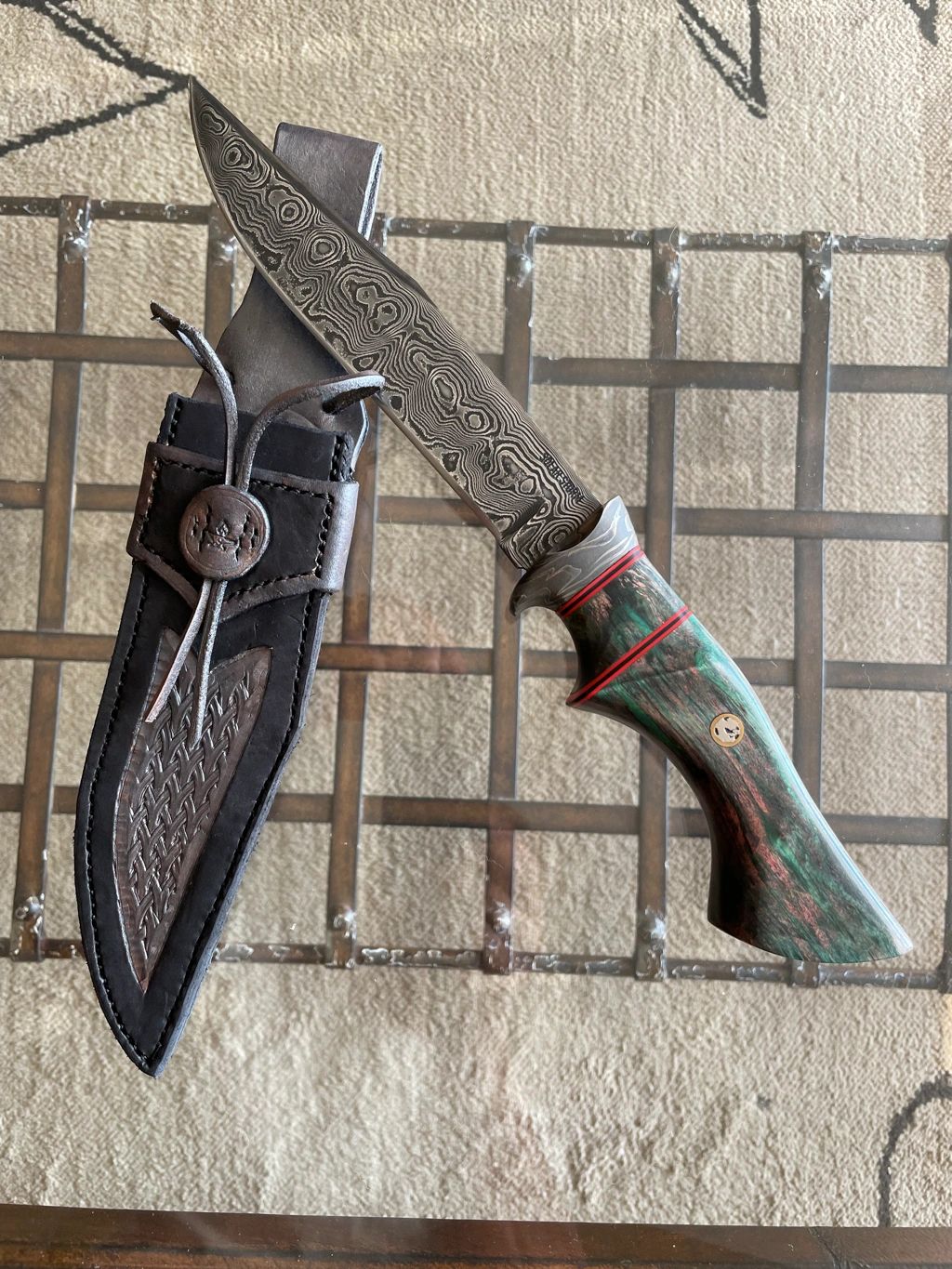

Number three in the books. Blade actually came out how I drew it before I started forging, so that's a positive. Bolster slid down the handle during glue up, and I didn't notice. Palm swell may be a little too far back. But overall, feels comfortable.

I Just joined ABS this month. I built a gas forge & a 2X72 grinder the summer of 2020. The summer of 2021 was my 1st attempt of making blades. The attached pictures are of a wakizashi forged of 5160 steel; with copper furniture that I made from old copper pipe.

Hi all, here is a photo of my latest, a 9” chefs knife with purpleheart handle scales and brass pins. The blade was forged from a rather large coil spring I found in a McDonalds parking lot of all places. Hopefully the new owner of this one will use it to make something a bit healthier.

Recent Knife I made(Gift for my Sister). I think this is my 12th Knife ever. 11.75" long, 2.125" wide Blade, India Rosewood scales, nickel pins. First real attempt at handsanding, I need to make some sanding blocks to say the least, and more grit varieties. This was forged from a bar of 5160, 1.5" wide bar stock.

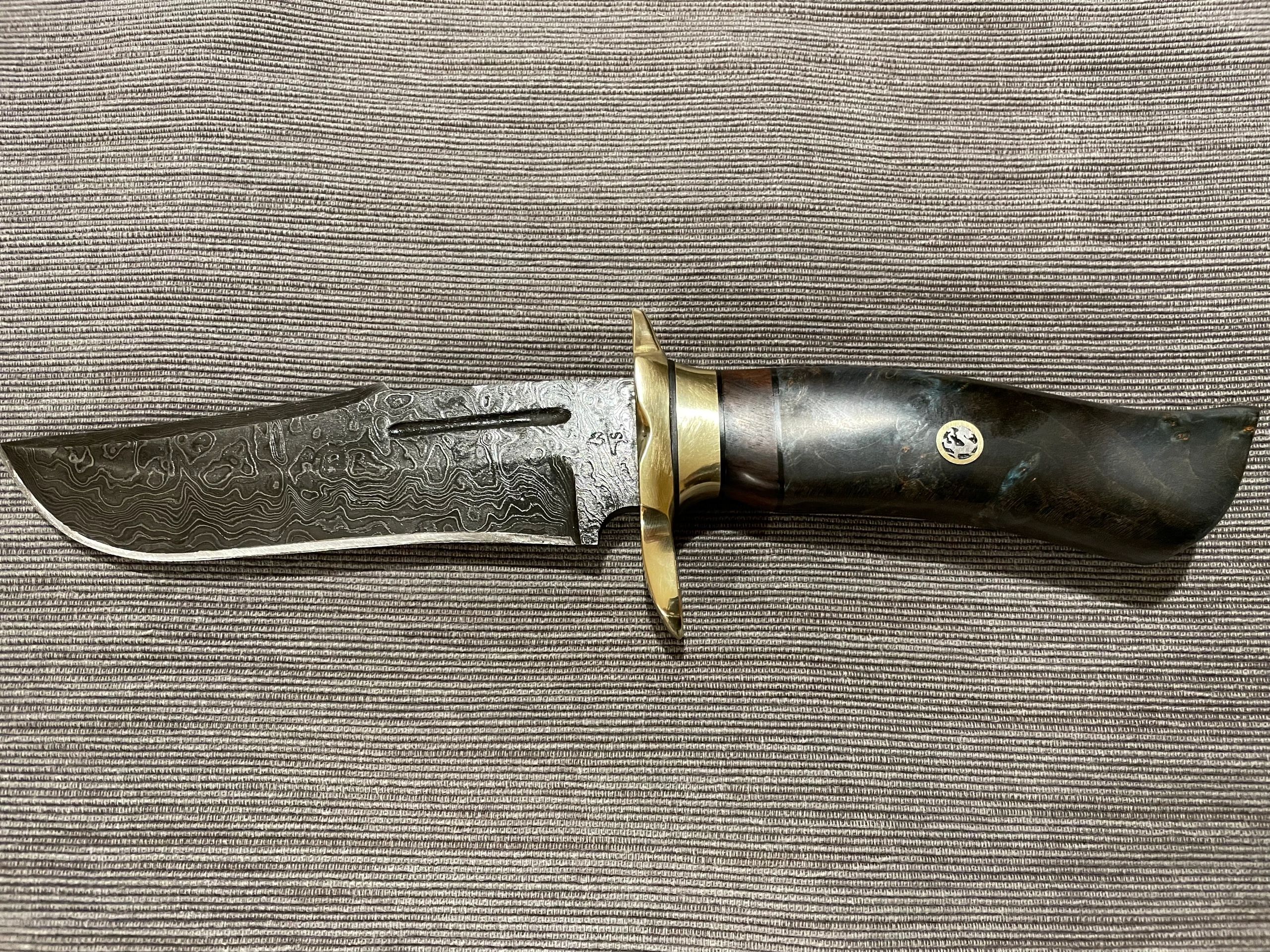

A few things from the last 6 months.

Hi everyone,

I'd like to apologize now, I've never used a forum and I am fairly horrible when it comes to most things involving the internet. With that stated, I can't figure out how to post more than one photo at a time so I'll be doing some quick succession show and tell style posts. (9 Knives in 8 photos)

This (like all my blades) is made from 1084, it was the first attempt forging a blade and seemed fitting to be the first to get finished. Its has a forged mild steel guard, I tried hot punching it but that was less than successful. The handle is made from reclaimed oak and treated with boiled linseed oil and wax.

My early knives were forged as part of the Intro class at NESM last October (2021). For my second finished knife I did a purely stock removal approach on the guard (1/4" mild steel) and improved upon my handle shaping as best I could. The handle is from the same piece of reclaimed oak as my first knife and was given as a gift to my brother.

This is my first attempt at a chef knife, 1084 with a micarta bolster, olivewood handle and a thin copper spacer. After I passed this on to my friend, this picture, with the clearly visible sanding zones on the blade and the rectangular bolster and handle shape, really began to bother me. I plan on getting this knife back for some touch up work in the coming months.

This is a pair of "His and Her's" hunting knives. They would be the 4th and 5th knives I'd ever completed and the first full tang knives I had put handles on. The handle materials are kirinite with vulcanized paper liners and copper pins. The larger knife was forged with a specific large handed individual in mind, he loved it so much he got the regular one for his girlfriend.

Knife #6: Nessmuk Skinner, the S-guard was forged from mild steel then heat blued. The handle is Padauk with a copper pin, it is comfortable but I don't find it entirely aesthetically pleasing.

This clip point hunter was made during the Intermediate class at NESM April 2022 and marked my 7th completed knife. It has a stainless steel guard and stabilized walnut burl handle. The handle is a little on the heavy side but I find it comfortable and I was never planning on giving away/selling it.

This offset pairing knife was forged prior to my intermediate class and finished after. It wasn't planned out in the least and was more of a blow off steam kind of forging.

The handle is mahogany with a stainless steel bolster and copper spacer. This was my first knife finished in my home shop, start to finish.

Finally #9: Second knife completely in my own shop. Another clip point hunter, a lot less flare in the handle due to material constraints. The guard is stainless steel and brass, transitioning into a stained curly maple handle.

Again, my apologies for not being able to figure out how to post more efficiently.

M. Bell

Some of my work

3rd Knife - first attempt at stabilizing wood

4th knife - tried my hand at casting pine cone scales

5th knife - going bigger

6th knife - experiment with everything. casting copper mesh scales

7th knife - custom order using customers antler. First attempt at a damascus Cu Mai.

Honest Critiques welcome.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke