My first forged knife. Didn't really have a design in mind, just sort of freestyled to get used to everything. I have no experience with blacksmithing so it was certainly a learning experience!

This is the first knife that I made. I just recently finished it with great guidance and patient teaching from Wes Byrd j.s. These are progression pictures. 5 unfinished ones and 5 finished ones. Enjoy!

Just finished my first hand forged knife. I modified a Canadian belt knife style skinning blade that I had. The goal was a light weight pack knife good for gutting, skinning, caping, and boning, that would work on small to large game. The steel is Aldo's 1084 and the handle is a simple epoxy soaked jute wrap to keep it slim plus a good grip when wet and gory from doing its job. Learned a lot about things to do better next time, but still pretty damn happy with the way it turned out. I'm going to give this one to the wife for mothers day. Can't wait till hunting season to see how it performs

New guy here. I have always been a tinkerer but only started knives 2 years ago. I enjoy building the tools as much as the knives! I love forums and boards. I am more or less self taught and boards like these are how I puzzle things out. Here are a few of my examples.

Those are some nice knives Jason. Looks like good clean work. Thank you for sharing.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Thanks a bunch. I don't get a lot of feedback from folks other than the wife or the people I give the knives to. Of course gift recipients always say they are good and the wife loves me so it is nice to hear it from another source!

Here are some of mine:

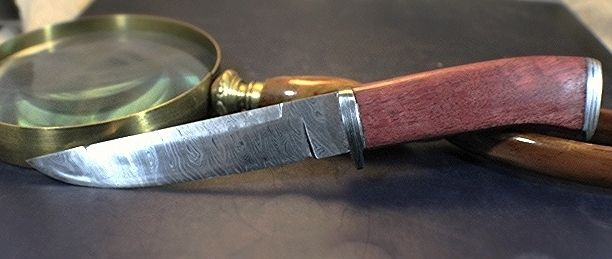

maiden's hair and purple heart. Peened tang.

W2 hunting knife for friend's adult son or daughter.

I have pics from Coop of the nicest things I ever made in the Introduction thread, if you want to see a messer and a jian.

I hope to continue improving and I am glad to be part of this group. It is intimidating at times, but also inspirational and supportive.

Thanks,

kc

Real nice. How are you getting that hamon? Edge quenching?

nope. Just plain ole satanite. However, that steel is Aldo's 1075 (which means it isn't really 1075, but, "water-hardening, high-carbon" steel). Everyone calls it 1075 because it has somewhere around 76pts of carbon. But, true 1075 is supposed to have a minimum of .4% manganese, or something near that.

This is what Aldo provides: Certification: C- .760 Si- .240 Mn- .350 P- .0100 S-.0010

I believe him on this. This lower manganese is a problem for industry, but it is a good thing if you want to make a hamon.

I was one of the first to buy this steel from him, and I love it.

Why?

Because it is a simple, hypoeutectoid (or eutectoid) steel. That means that you do not have to soak it at temperature prior to quenching in order to get the most out of it. You can bring the steel up to temp, and then quench it, almost immediately.

This means that, with care, the area under the clay is just barely up to the austenizing temp, maybe even below it, at the time of quench. So, it was not an edge quench, but the edge of the blade, and up to the clay, was the only part of the blade that was hot enough to harden.

Don't get obsessive about it, but try to keep the temp pretty low (about 1450-1480).

Great kinves Kevin and thanks for the advice on Aldo's 1075.

Here are a bowie knives Ive made recently. made from 1095 and with hamon. hidden tang. thanks for looking. this knife is happy in its new home.

thanks again for looking

Tucker Parris

Hello to all. I do not know if this is an introduction page?? A place to introduce myself to the knife community. So I'll await confirmation. But in the mean time, submit a photo of one of my pieces, forged 5160? Bumper bracket from a 1946 Plymouth Coupe. The style was modeled after the Legend of The Falls movie. Openly ask for advice and looking forward to rewarding experience with you all.

Hap Smith Jr. 2112 8531

U.S. Marine Corps (retired)

|quoted:

Here are a bowie knives Ive made recently. made from 1095 and with hamon. hidden tang. thanks for looking. this knife is happy in its new home.

thanks again for looking

Great work. I'm new here and have been browsing pictures, wow. Talent.

Hap Smith Jr. 2112 8531

U.S. Marine Corps (retired)